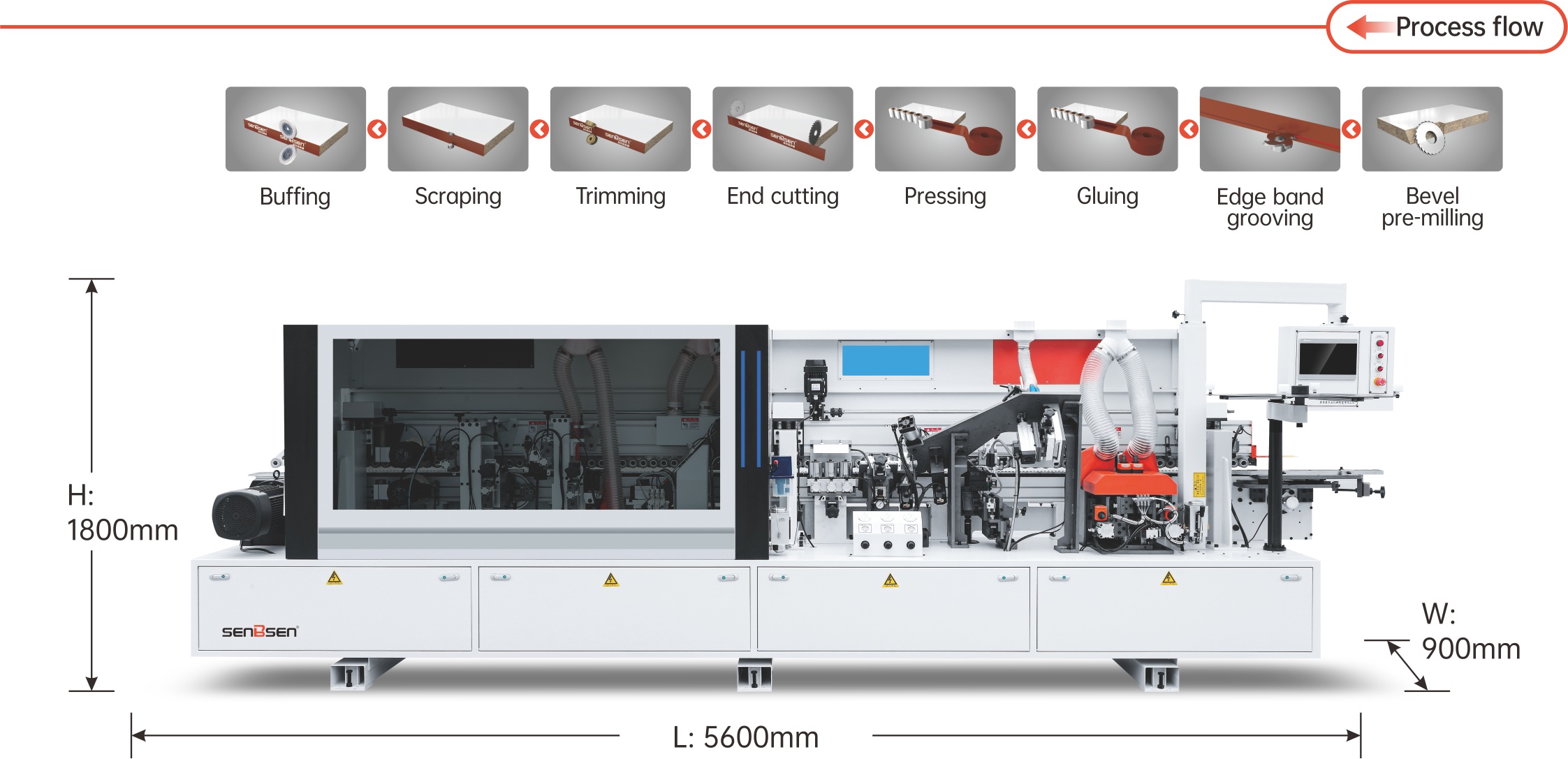

Strict control is exercised throughout the edge sealing process, including pre miling of beveled edges, grooving of edge strips, gluing molding and pressing, front and rear alignment, finishing, edge scraping, and polishing. After multiple rounds of quality inspection and repeated debugging, we have achieved smooth and firm edge sealing with perfect details,providing a solid guarantee for furniture quality.

|

Model |

SBS - 620J 45°automatic edge banding machine |

|

Sheet length |

>120mm |

|

Input voltage |

380V |

|

Sheet width |

>120mm |

|

Input frequency |

50HZ |

|

Plate thickness |

15 - 25mm |

|

Air pressure |

0.6Mpa |

|

Sealing tape thickness |

0.6 - 1.5mm |

|

Total power |

20kw |

|

Feed rate |

8 - 10min |

|

Machine dimensions |

5600*900*1800mm |

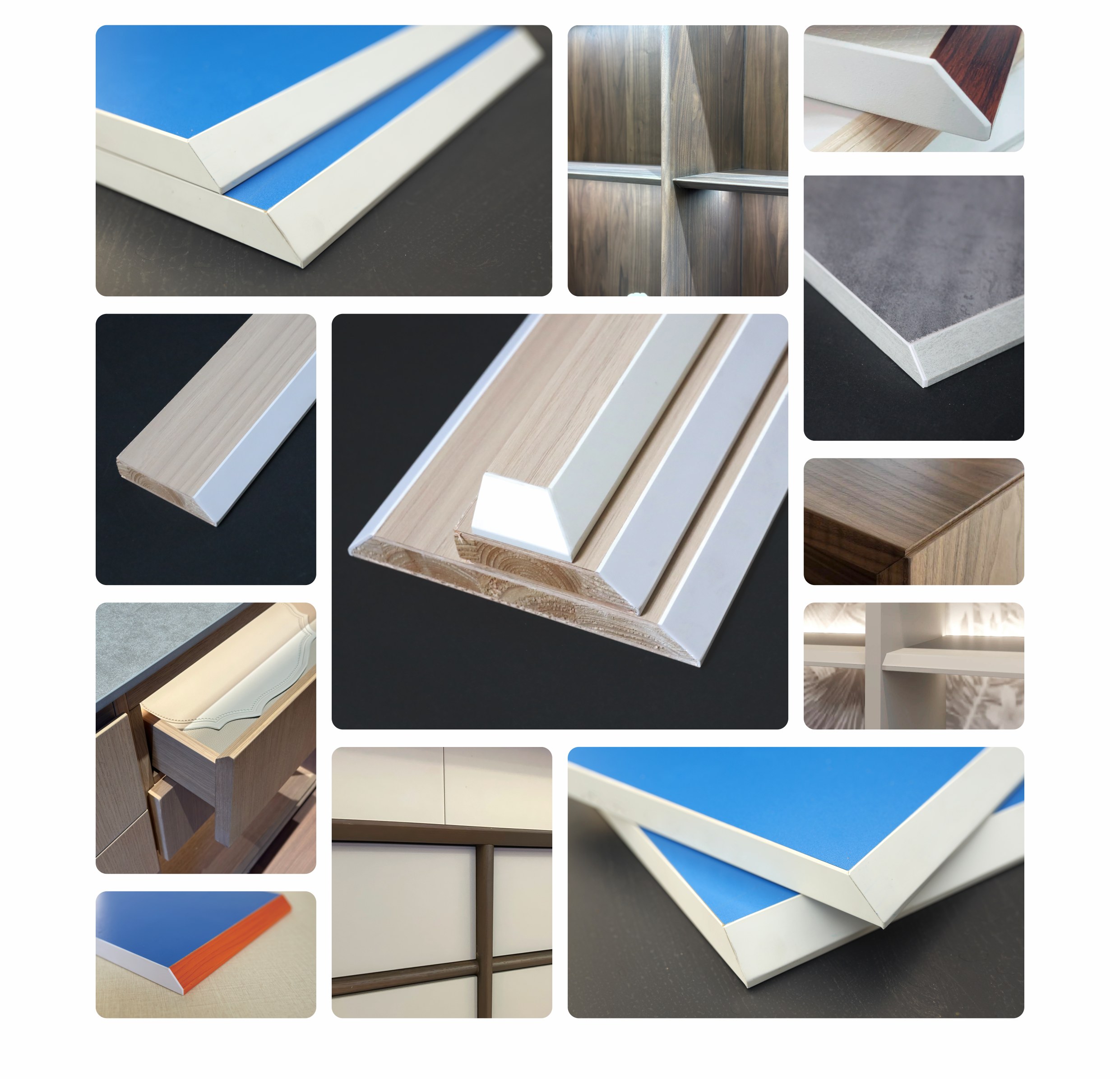

Various artificial boards such as density boards, particle boards, multi-layer boards, aluminum honeycomb boards, etc.,batch customized furniture such as office furniture, cabinets, bathroom cabinets, etc.

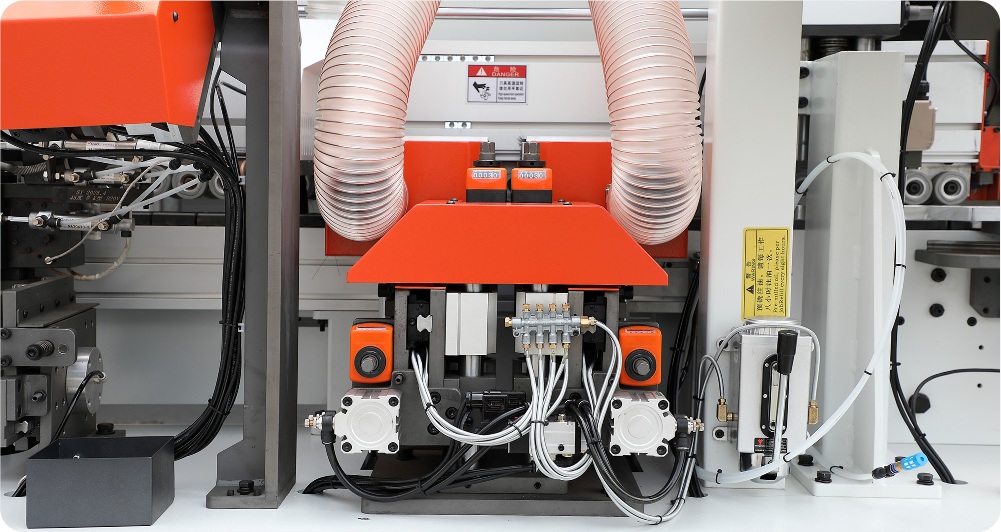

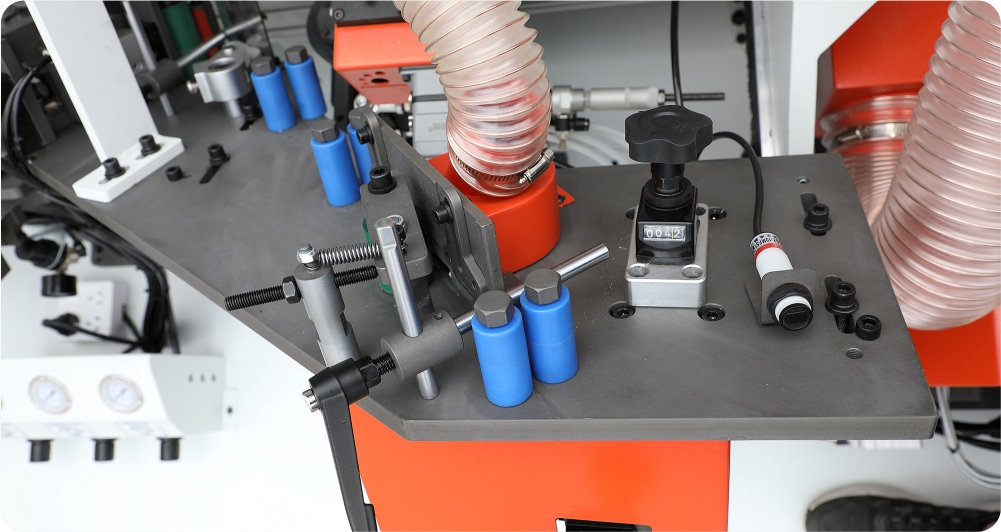

Self-developed glue

Adopting the integrated glue pot developed by Senbaisen, with a reasonable structure,Small footprint,perfect edge sealing effect Optional PuR glue coating machine, PuR edge sealing is environmentally friendly,and the quality of the sealed board is high.

Width of bevel≤2mm

The four sides of the plate can be made into oblique straight sides at the same time, and the minimum width can be 2mm.

Bevel pre-milling

Specially designed for beveled edges, it usually supports edge sealing preprocessing for 45 ° beveled and straight edges.

Edge banding grooving

According to the preset angle, groove the inner side of the edge banding to facilitate bending and pressing, ensuring the quality of pasting and preventing edge bursting.

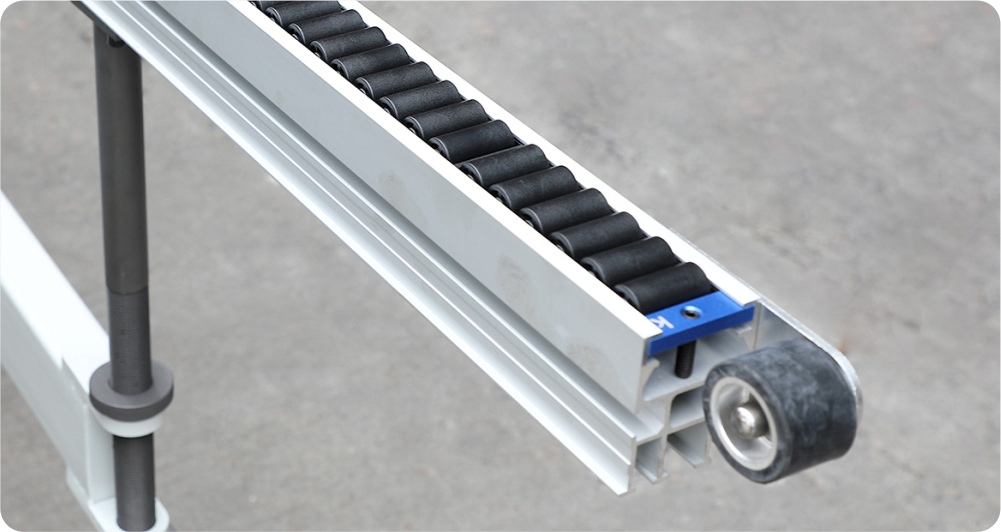

Non powered sliding rail

Supporting and guiding the smooth sliding of the board to improve the efficiency and quality of edge sealing operations.