Adopting a 2+1 driling package mode, it integrates drling/miling functions into one machine, with multiple functions seamlessly connected to multiple disassembly software,quick positioning, and the abiitly to achieve six sided punching, slotting, and handle free processes. it also has a buit-in diversified process database for quick access, greatly improving production flexibility and operational efficiency.

|

Model |

SBS - CNC6228 CNC six - sided drilling |

|

Workpiece length |

70 - 2800mm |

|

Workpiece width |

30 - 1200mm |

|

Workpiece thickness |

9 - 60mm |

|

X/U Maximum gripper speed |

130m/min |

|

Maximum Z/W axis speed |

35m/min |

|

Maximum speed of the Y/Y1 / V axis |

90m/min |

|

Upper vertical drill |

24 个 |

|

Horizontal drill |

16 个 |

|

Down drill |

9 个 |

|

Upper spindle power |

6kw |

|

Lower spindle power |

3kw |

|

Package power |

6.6kw |

|

Gross power |

28kw |

|

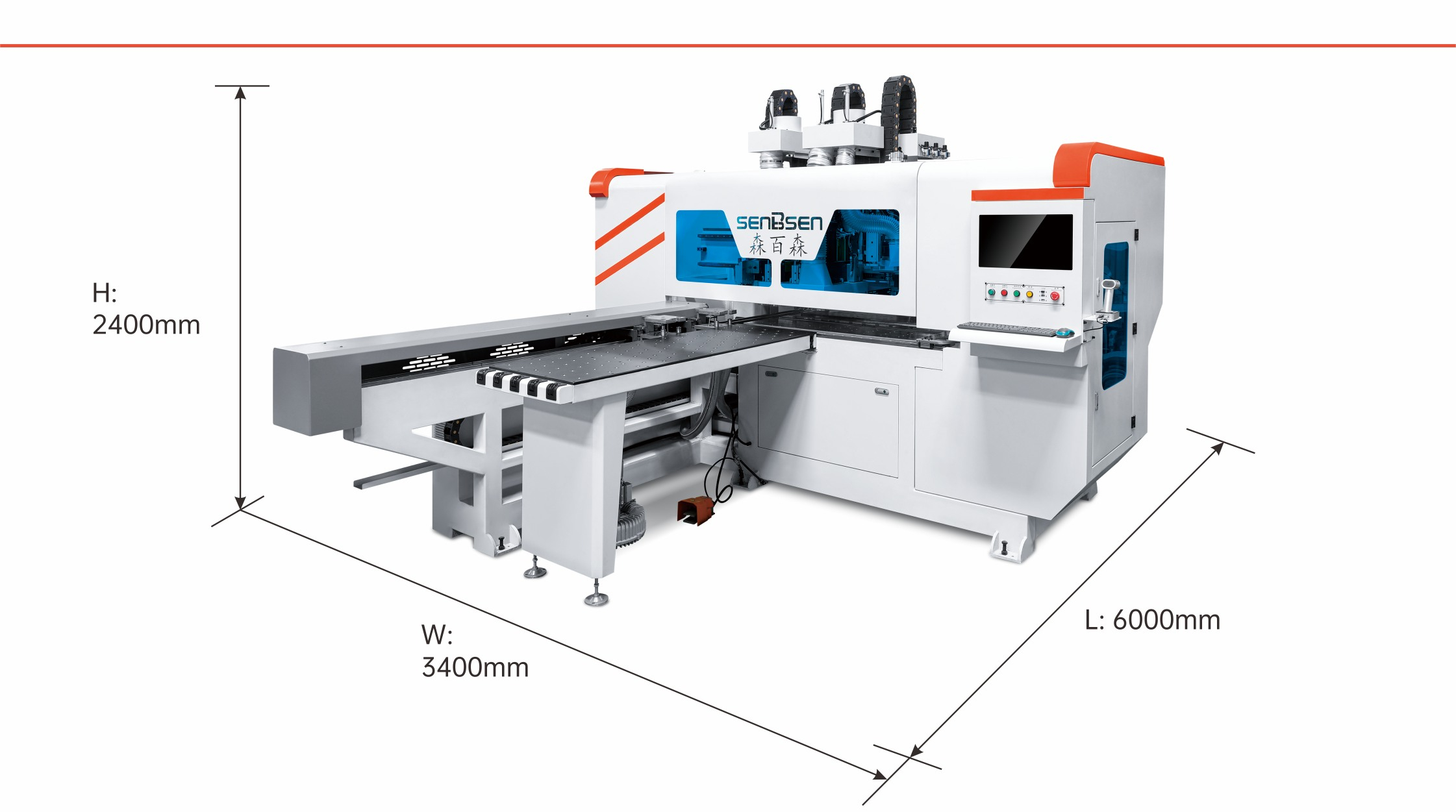

Overall dimension |

6000*3400*2400mm |

Various artificial boards such as density boards, particle boards, multi-layer boards, aluminum honeycomb boards, etc.,

batch customized furniture such as office furniture, cabinets, bathroom cabinets, etc.

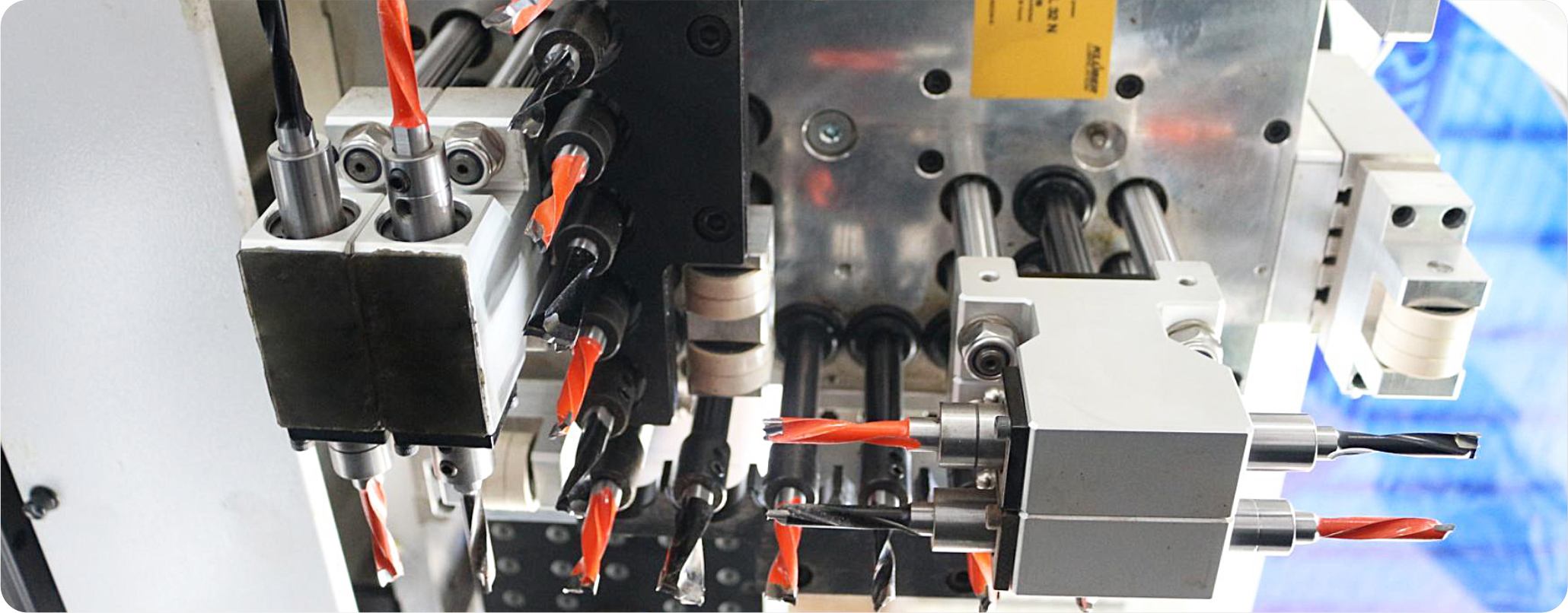

High precision drill bag

1.2+1 driling mode, linked processing, can achieve six sided punching, groove drawing, various handle free processes, etc.

2.The minimum spacing between dril packs is 64mm, and the frog jumping technique increases the overall drilling speed by 30%.

3.Paired with a rotary line, one person can complete loading and unloading, reducing the intensity of manual handling.

4.Eauipped with air fotation workbench and air flotation pressure plate for various sheet metal processing needs, achieving automated production.

Straight row 6-knife magazine

Independent telescopic six tool magazine, equipped with differenttypes of cutting tools according to its own processing needs,automatically changing tools to meet different processing techniques.

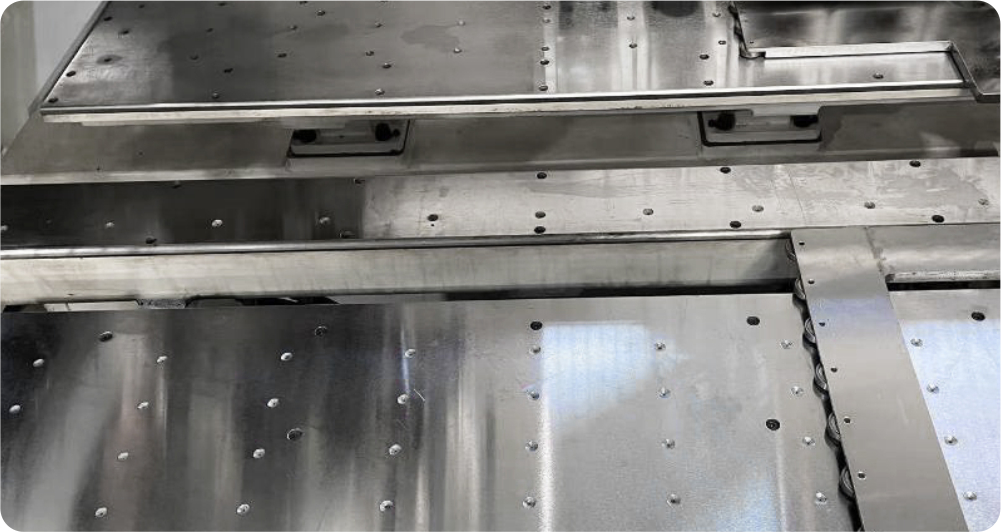

Double gripper guide rail

High speed long-distance double gripper structure reduces thenumber of gripper changes, making work more efficient andprecise positioning.

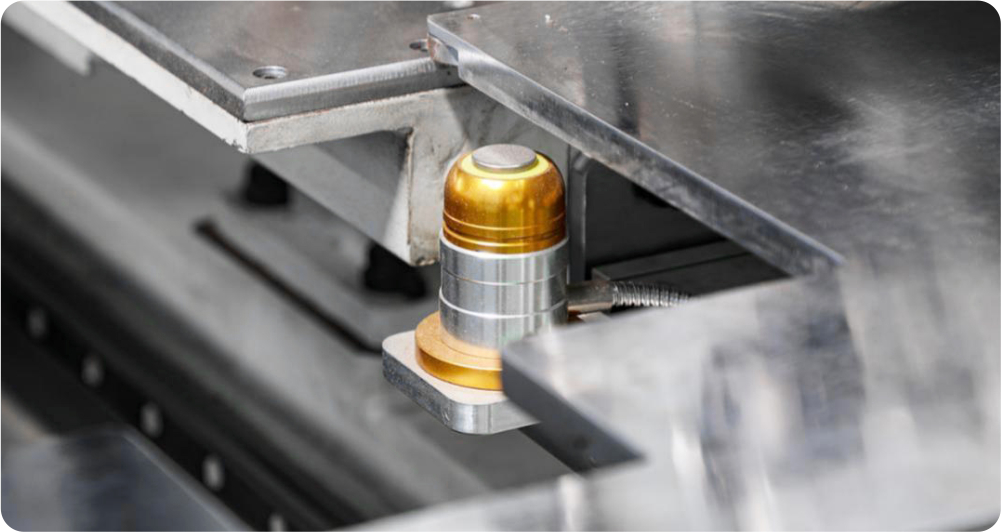

Accurate knife alignment device

Effectively avoiding manual tool alignment errors, intelligentlydetecting tool length, and improving efficiency and accuracy.

Electroplating high gloss anti scraping table top

The movable chrome plated processing table automatically adjusts itsposition during processing, providing a wider support surface and reducinghole position deviation caused by the rocker.