One machine is versatle, easy to operate, with multiple processing modes that can be switched with just one click. it can achieve processes such as three in one hole, wood chip hole, blind hole, sloting, invisible parts, Ramino, hinge hole, straightener,invisible handle,etc, meeting different processing needs ,it is automated with high precision and efficient processing without worry.

|

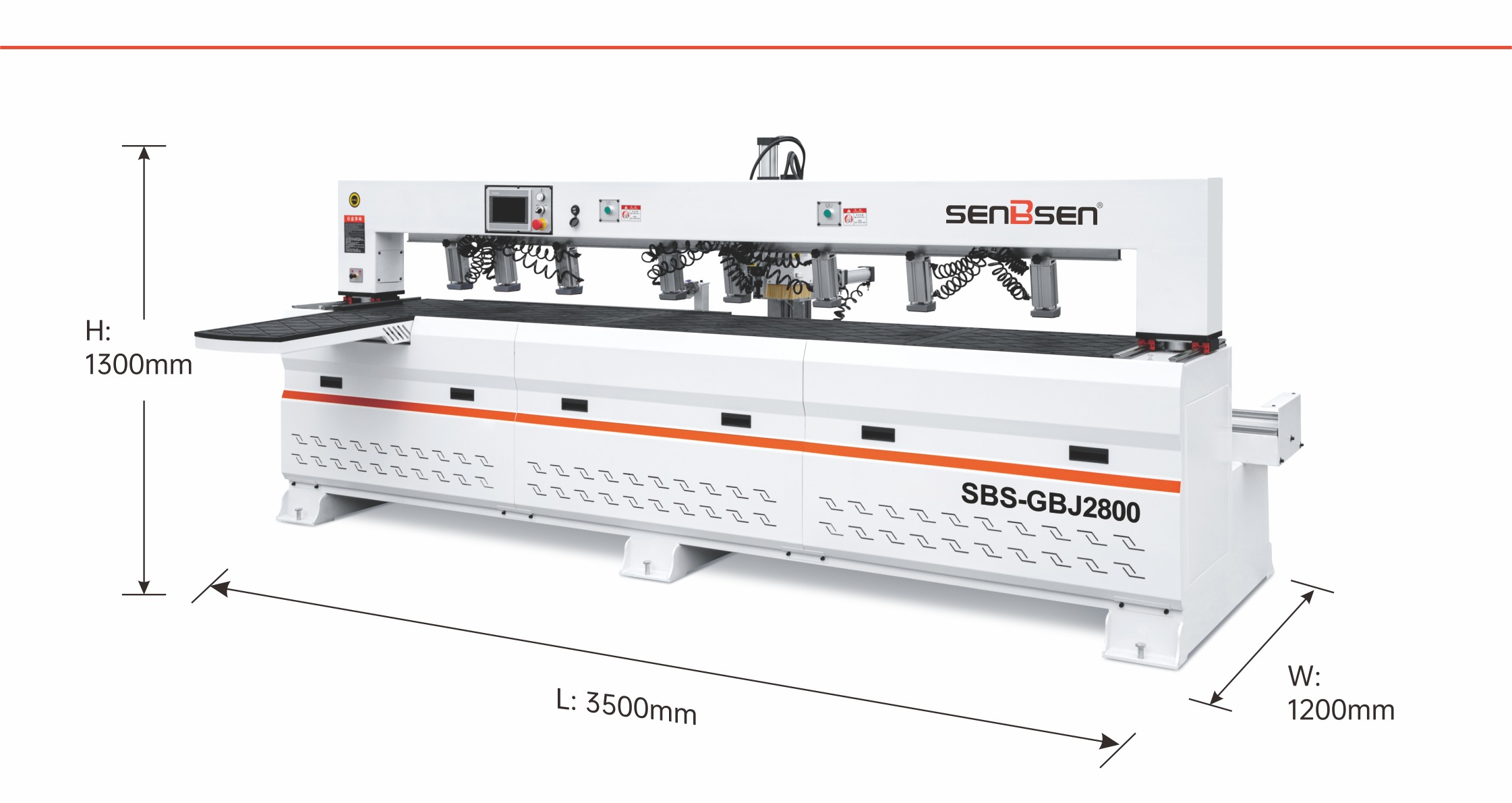

Model |

GBJ - 2800 CNC side hole drill (three spindle) |

|

Blank speed |

30 - 45m/min |

|

Drilling motor power |

2.2kw*2, 3.5kw |

|

Working speed |

8 - 20m/min |

|

Feed motor power |

0.75kw*3 |

|

Hole size |

3 - 15mm |

|

Gross power |

6.5kw |

|

Borehole depth |

0 - 35mm |

|

Overall dimension |

3500*1200*1300mm |

|

Workpiece thickness |

10 - 50mm |

Satisfy processes such as door lock holes, hinge holes, begonia angles, 45 degree beveled edges, mortise and tenon joints,

blinds, light cable trays, and handle free design.

Three spindle machining unit

1. Three spindle collaborative machining, with two horizontal spindles and one verical spindle, achieves one-time efficient and precisemachining of vertical and horizontal hole positions.

2. Three spindle machining is used in conjunction with CNC to complete the processing of invisible parts, including blind holes, three in one,grooves, buckle holes, invisible handles, hinge holes, and straighteners.

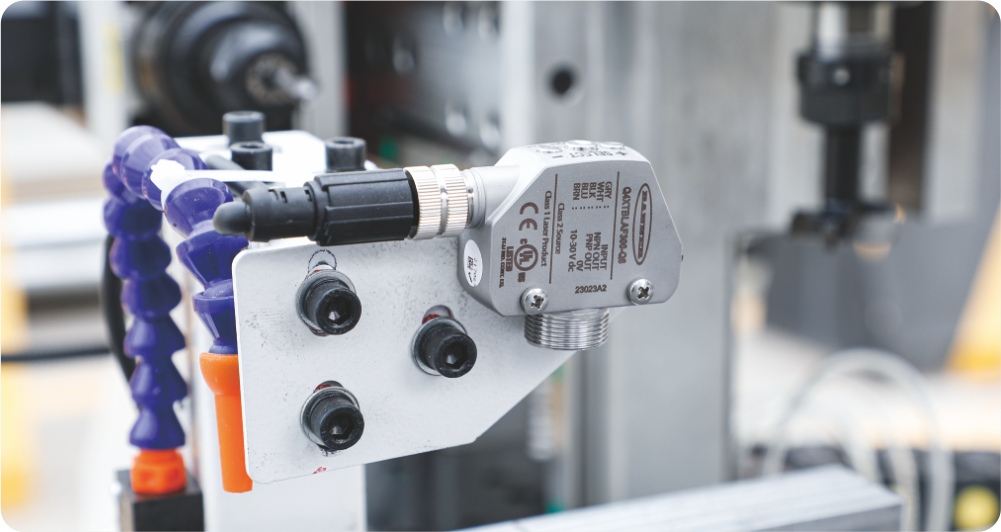

Laser induction Positioning (BANNER)

Imported laser probe, automatically scanning and measuring the length of the board, improving processing efficiency and accuracy

Mobile beam structure (precision rail)

Mobile crossbeam design, flexible to meet the processing needs of different sizes of boards, easy to adjust.

Operations Control System

Touch control panel, precise control, multi-mode free switchingeasy to learn.

Multi-point cylinder compaction

The movable high-pressure cylinder can accurately fix the board and effectively avoid the displacement of the board during movement.