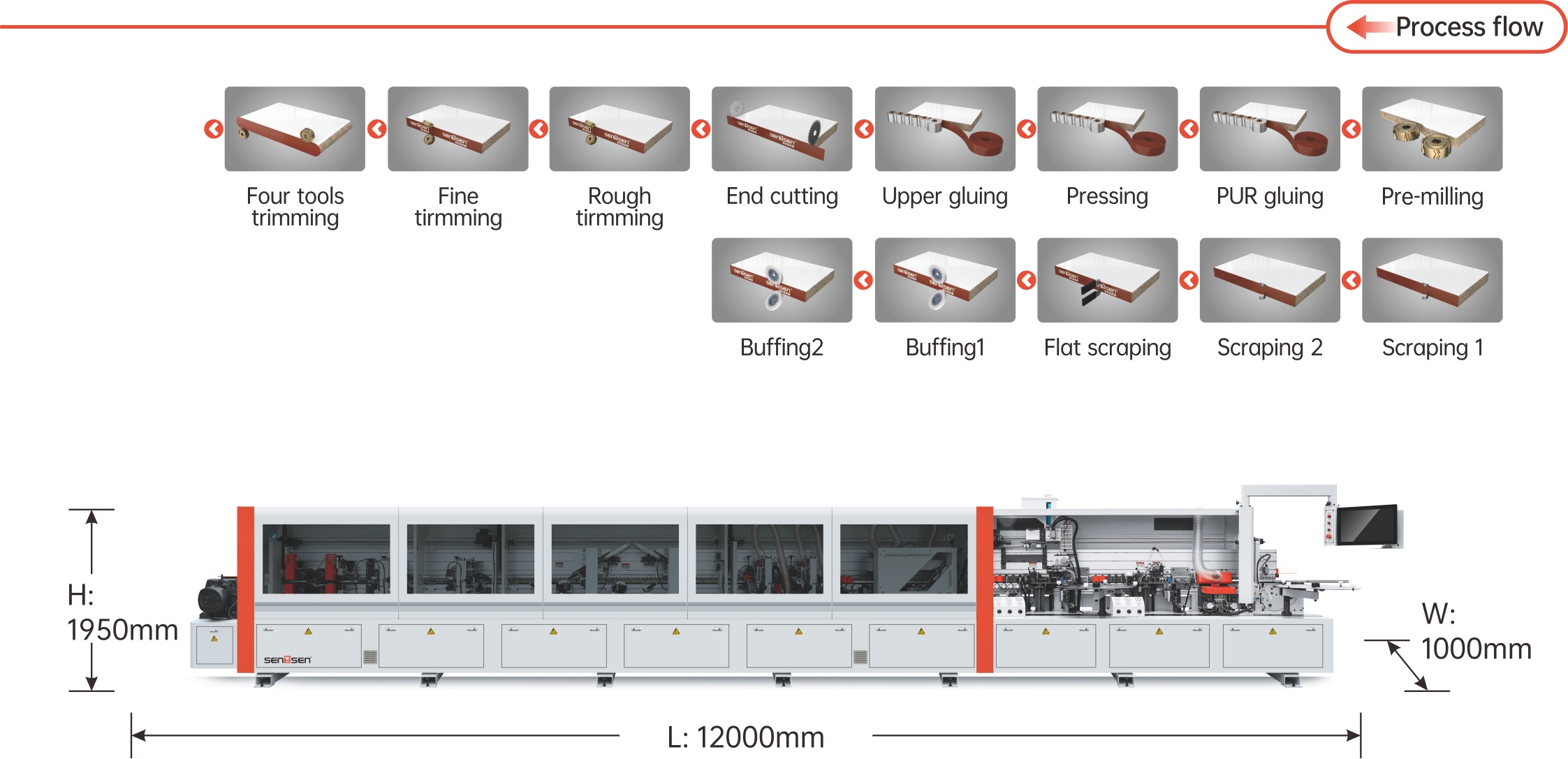

Strictly control the entire edge sealing process, including pre miling, PUR coating, adhesive bonding, upper adhesive bonding,double rail alignment, rough finishing, fine finishing, four blade tracking, edge scraping 1, edge scraping 2, flat scraping, polishing 1 and polishing 2; After multiple rounds of quality inspection and repeated debugging, the edge sealing is smooth and firm with perfect details, providing a solid quarantee for furniture quality.

|

Model |

SBS - GD935 Heavy duty narrow edge fully automatic edge banding machine |

|

Feed speed |

26m/min |

|

Edge band thickness |

0.3 - 3mm |

|

Plate length |

≥120mm |

|

Plate width |

≥55mm |

|

Sheet thickness |

10 - 60mm |

|

Input voltage |

380V |

|

Input frequency |

50HZ |

|

Air pressure |

0.6Mpa |

|

Total power |

28.8kw |

|

Machine size |

12000*1000*1950mm |

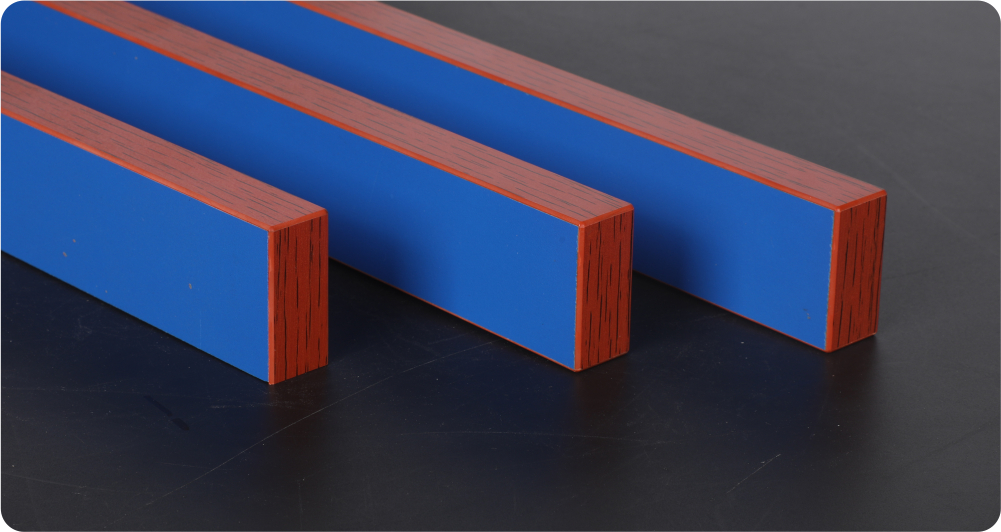

VVarlous artificial boards such as density boards, particle boards, multl-layer boards, aluminum honeycomb boards, etc.;

batch customized furniture such as office furiture, cabinets, bathroom cabinets, etc.

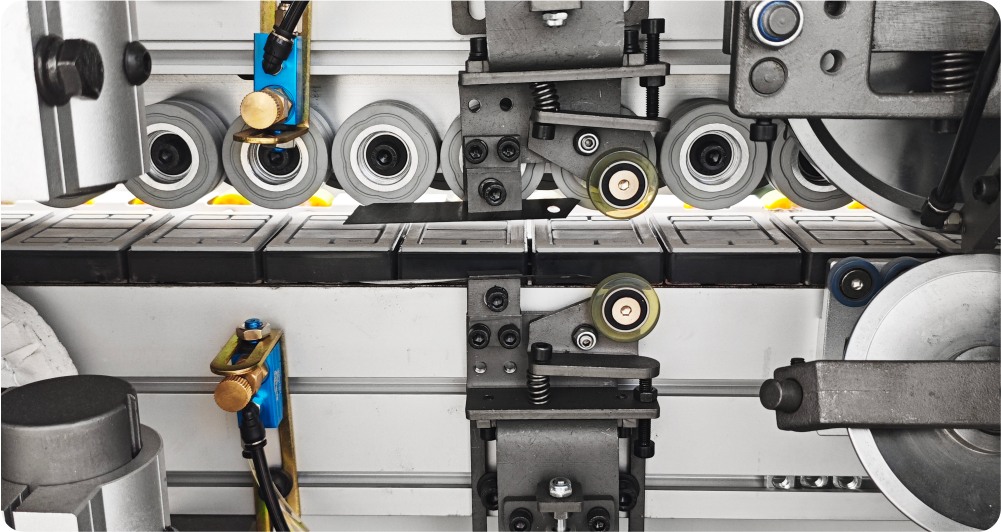

Flexible belt pressing

1.Automatic heating saves sol time, fast sol, and precise control of qlue.

2.The fastest start up time is only 15 minutes, and there is no need to wait for the glue to dissolve during mass production.

3.Avoid the trouble of manual qluing, work continuously, and prevent dry burning of the glue pot.

4.Equipped with a quick dissolving device, the upper and lower glue pots meet the requirements of both light and dark color edge sealing.

Narrow board edge sealing

38mm small wheel pressing material, 40mm narrow plate edge sealing.

Double guide end cutting

Above 300mm, four corner contour tracking can be opened,and the edge banding can be trimmed into a right angle arc shape.

Flexible flat scraper

Multi row cylinder linked pressure wheel,Apply vertical pressure to the beveled edge sealing tape.

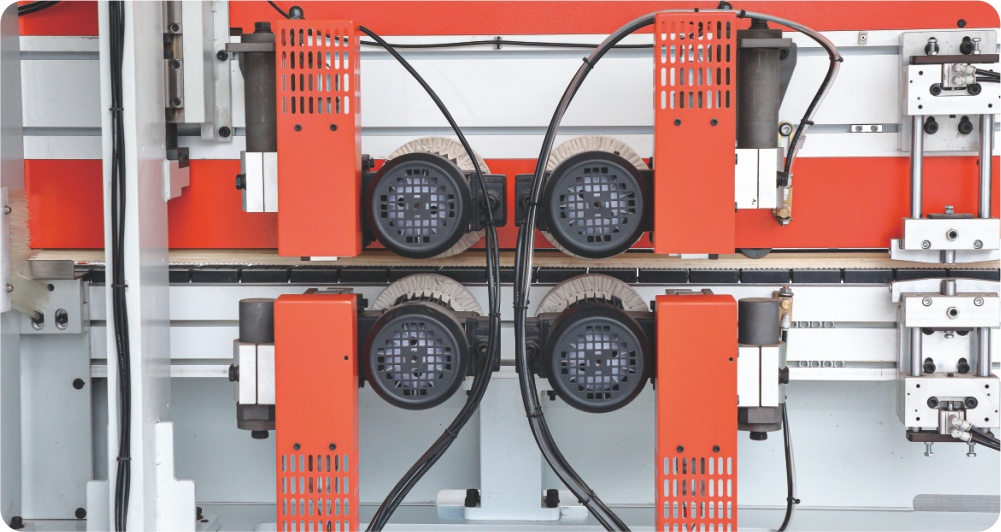

Electric polishing

The cotton polishing wheel cleans the board after edge sealing making the board cleaner and smoother after edge sealing.