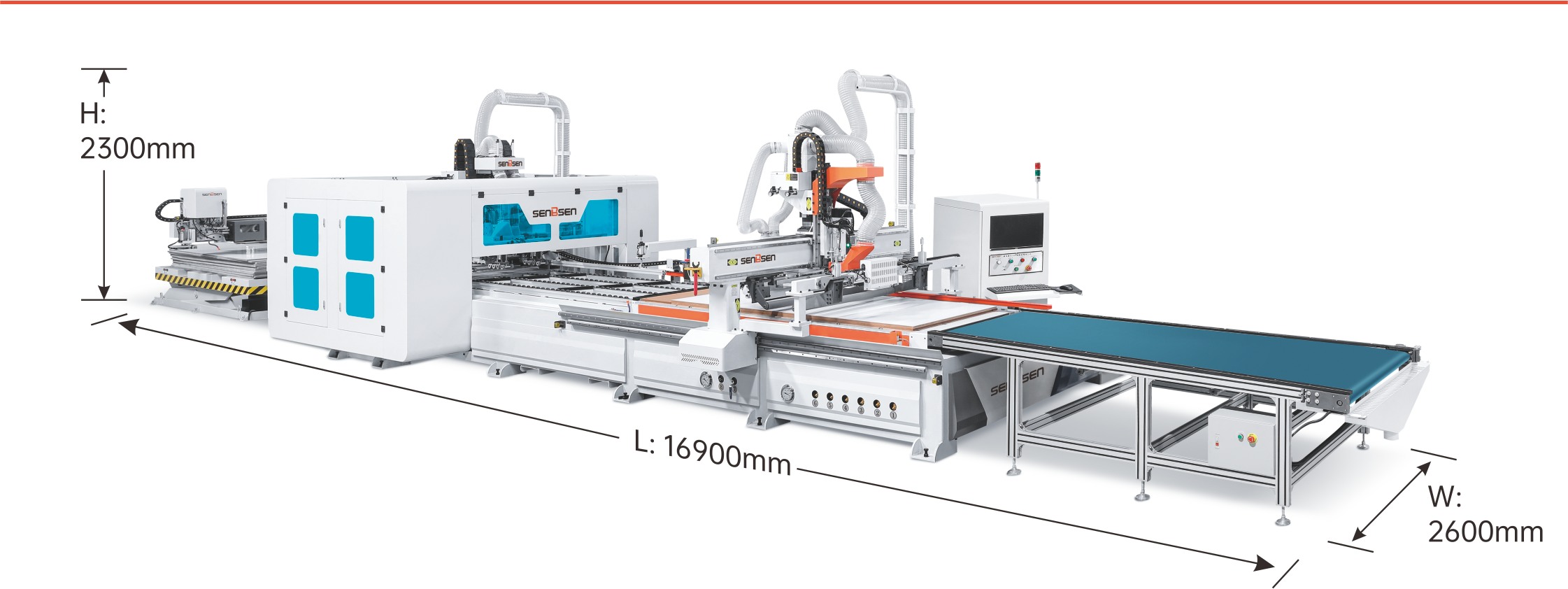

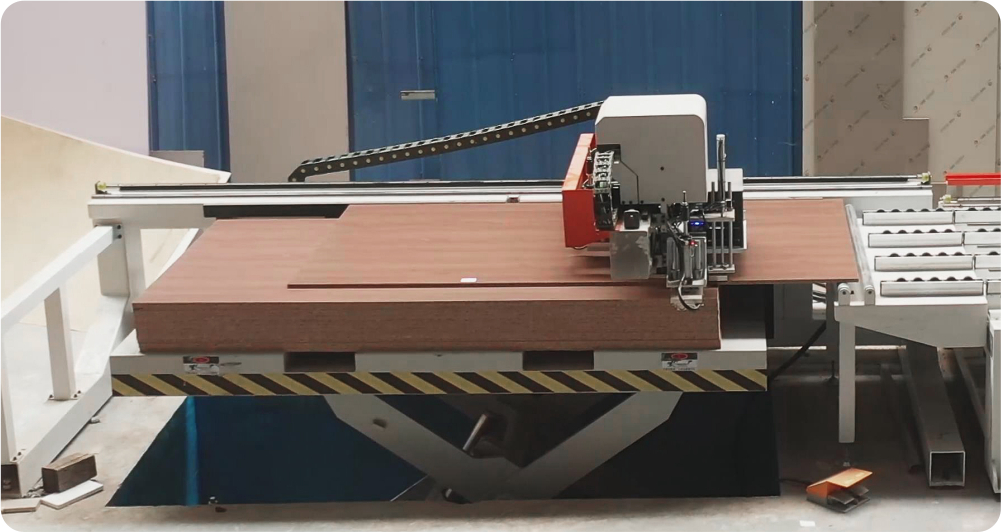

The driling and cutting integrated machine achieves integrated processing of multiple processes such as labeling,driling, cutting, etc, through functional integration,The equipment is easy to operate and can produce up to 120 boards per day.

|

Model |

SBS - GH9ZT Drilling and cutting integrated machine |

|

Processing Size |

2460*2800mm |

|

Cutting speed |

8 - 20m/min |

|

Spindle Power |

9.0kw air - cooled |

|

Vacuum Pump Power |

11kw/7.5kw |

|

Spindle Speed |

18000r/min |

|

Total Power |

25kw |

|

Traveling Speed |

65 - 80m/min |

|

Overall Dimension |

16900*2600*2300mm |

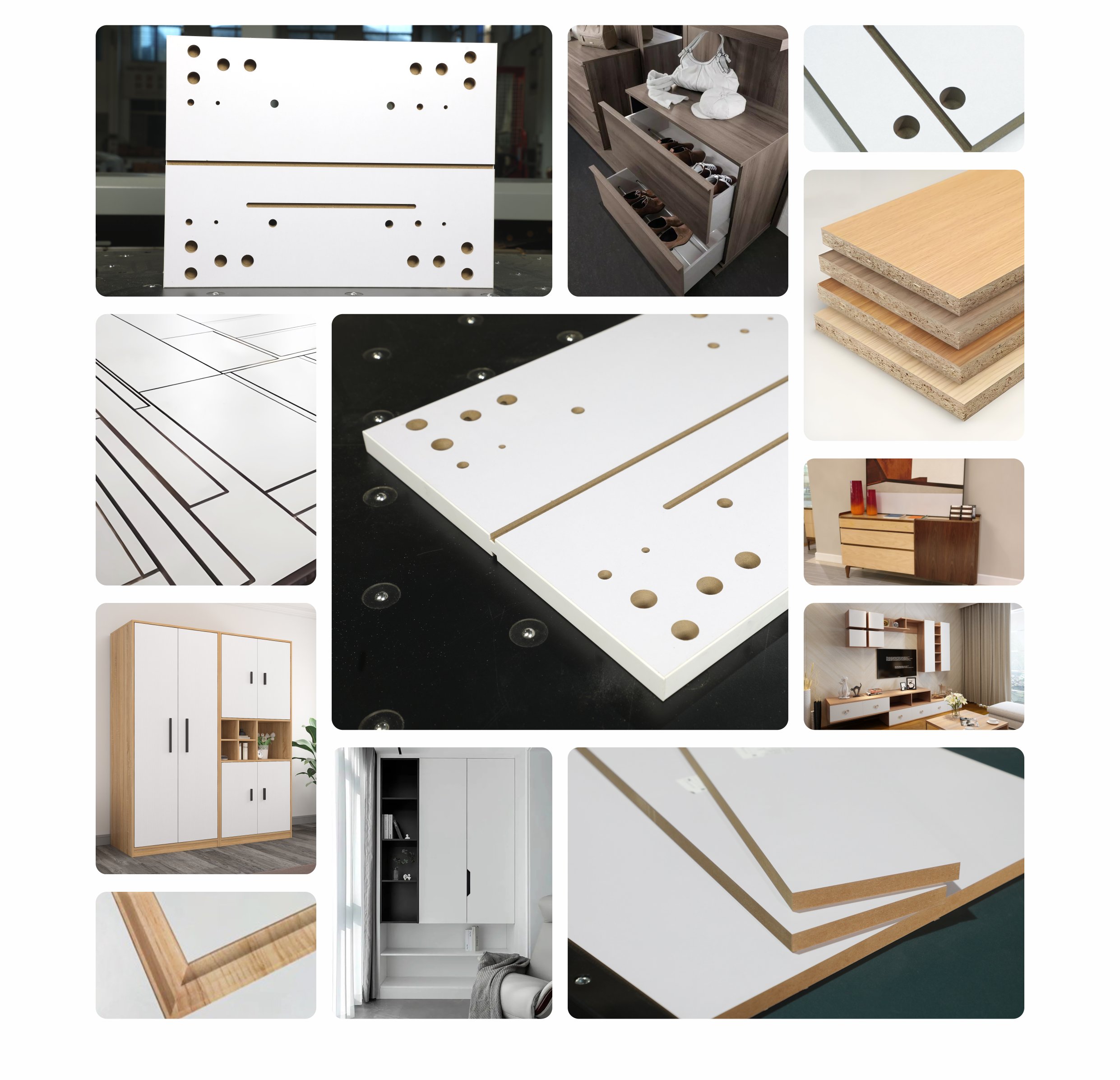

The machine can automaticaly complete the labeling, driling, slotting, cuting, and cuting of the board as an integrated procesing equipment. No need for manual flipping, double-sided punching and slotting can be completed in one go.

Cutting and punching integrated

1.Iintegrate automatic labeling, double-sided drilling, slotting, cutting and cutting functions into one.

2.By driling holes up and down with one positioning, there is no need to fip the board, and 120 sheets can be processed in 8 hours.

3.suitable for wood, particleboard, fiberboard, plastic and other board materials, meeting the diverse material needs of panel furniture.

4.0ptional side hole edge banding machine can be used to achieve integrated production of labeling, drling, slotting, cuting, and edae banding.

Lifting platform loading+labeling machine

The lifting platform automatically loads materials, which is convenient and fast, without the need for manual intervention,and improves production efficiency.

Precision drill bag

One high-precision drill bag on each side, with auxiliary pressure wheel for more stable processing. It can process plates with awidth of 1220mm and a length of 2440-2800mm.

Direct automatic tool changer magazine

The straight row knife magazine can hold 12 knives,with a high-speed spindle motor and automatic tool changing without waiting.

Belt conveyor for material feeding

Belt conveyor for material feeding, combined with push platefeeding to reduce manual operation.