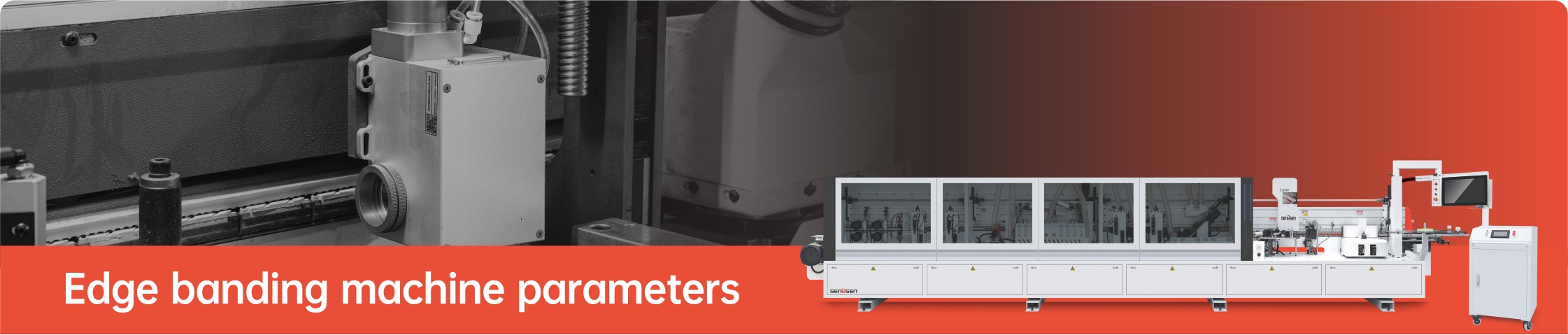

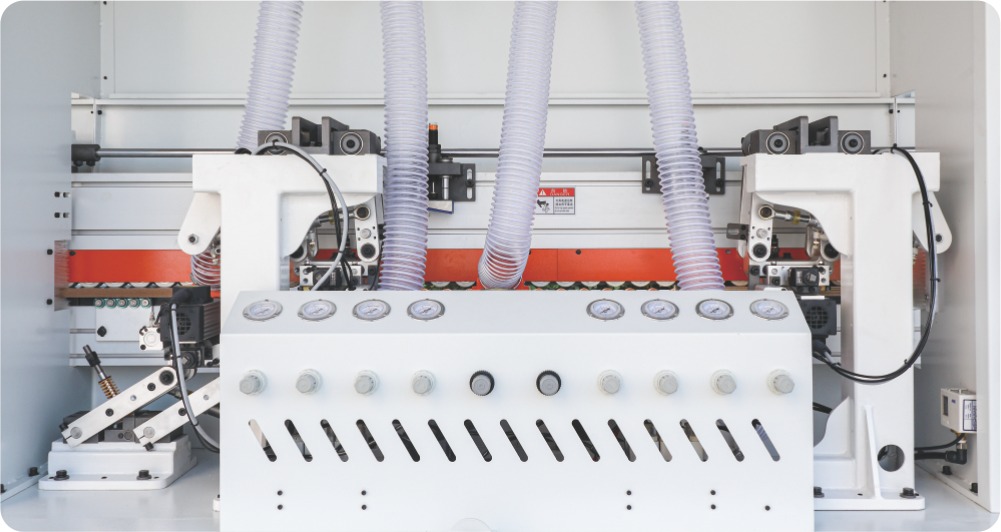

Strictly control the entire edge sealing process, including pre milling, PUR coating, EVA coating, lamination 1, laser edge sealing, lamination 1, and lamination 2Double rail alignment>rough repair>fine repair>four blade tracking>edge scraping 1>edge scraping 2>flat scraping>polishing 1>polishing 2;After multiple rounds of quality inspection and repeated debugging, we have achieved smooth and firm edge sealing with perfect details, providing a solid guarantee for furniture quality.

|

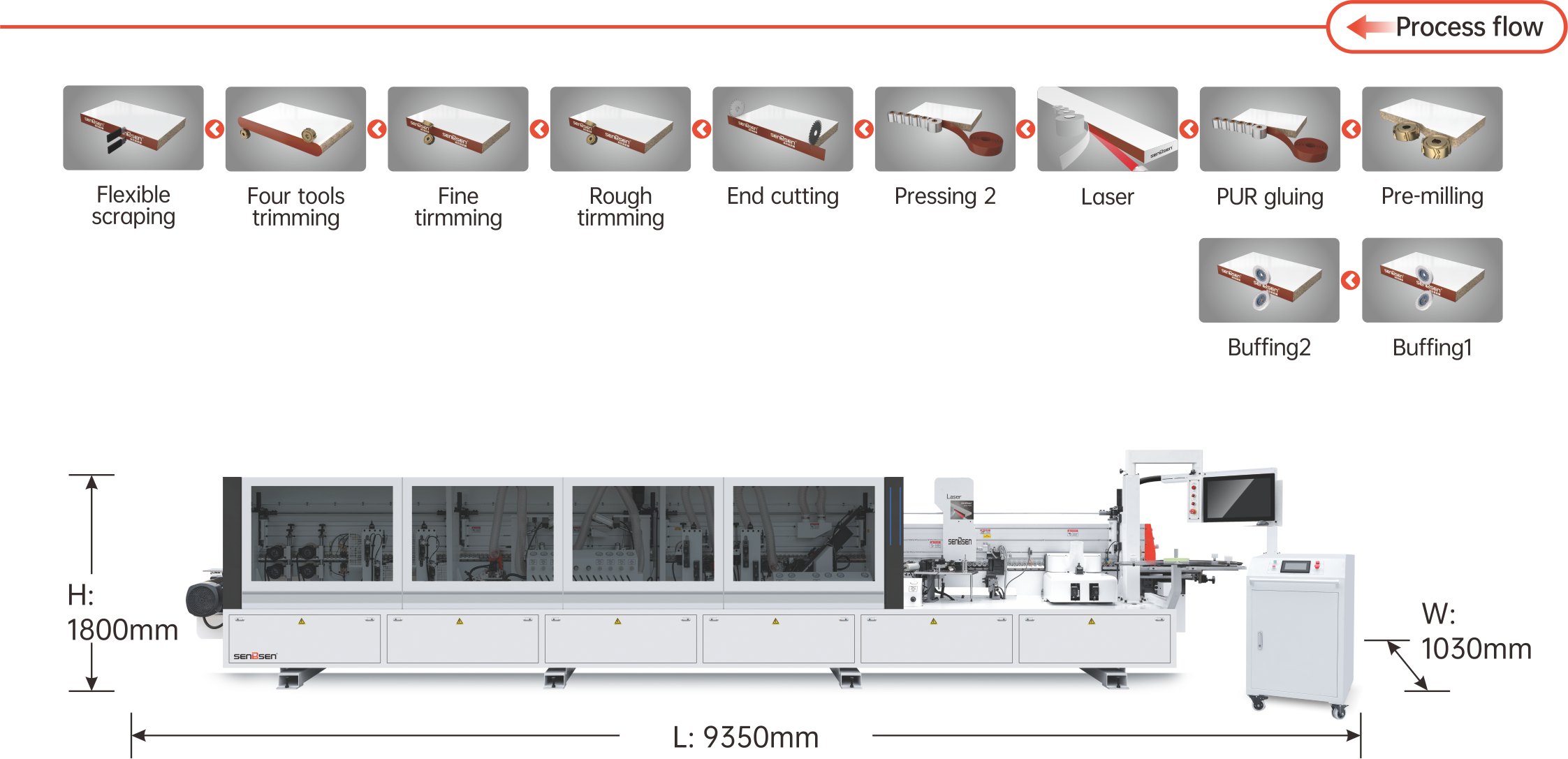

Model |

SBS - GS750 Intelligent laser heavy - duty steel beam edge banding machine |

|

Feed speed |

18 - 22m/min, 18m/min (with tracking enabled) |

|

Edge band thickness |

14-40mm |

|

Plate length |

≥120mm (≥200mm with tracking enabled) |

|

Plate width |

≥80mm |

|

Min. sheet size |

120*120mm, 200*80mm (Open tracking) |

|

Sheet thickness |

9 - 60mm (Laser sealing thickness 9 - 35mm) |

|

Sealing thickness |

0.4 - 3mm, 0.8 - 3mm (laser sealed) |

|

Input voltage |

380V 50HZ |

|

Air pressure |

0.6Mpa |

|

Total power |

24.5kw |

|

Machine size |

9350*1030*1800mm |

|

Laser power |

1.5kw/2kw (optional) |

|

Cooling and power |

Water cooling, 8.5kw |

|

Laser mode |

Laser, H maximum = 40mm |

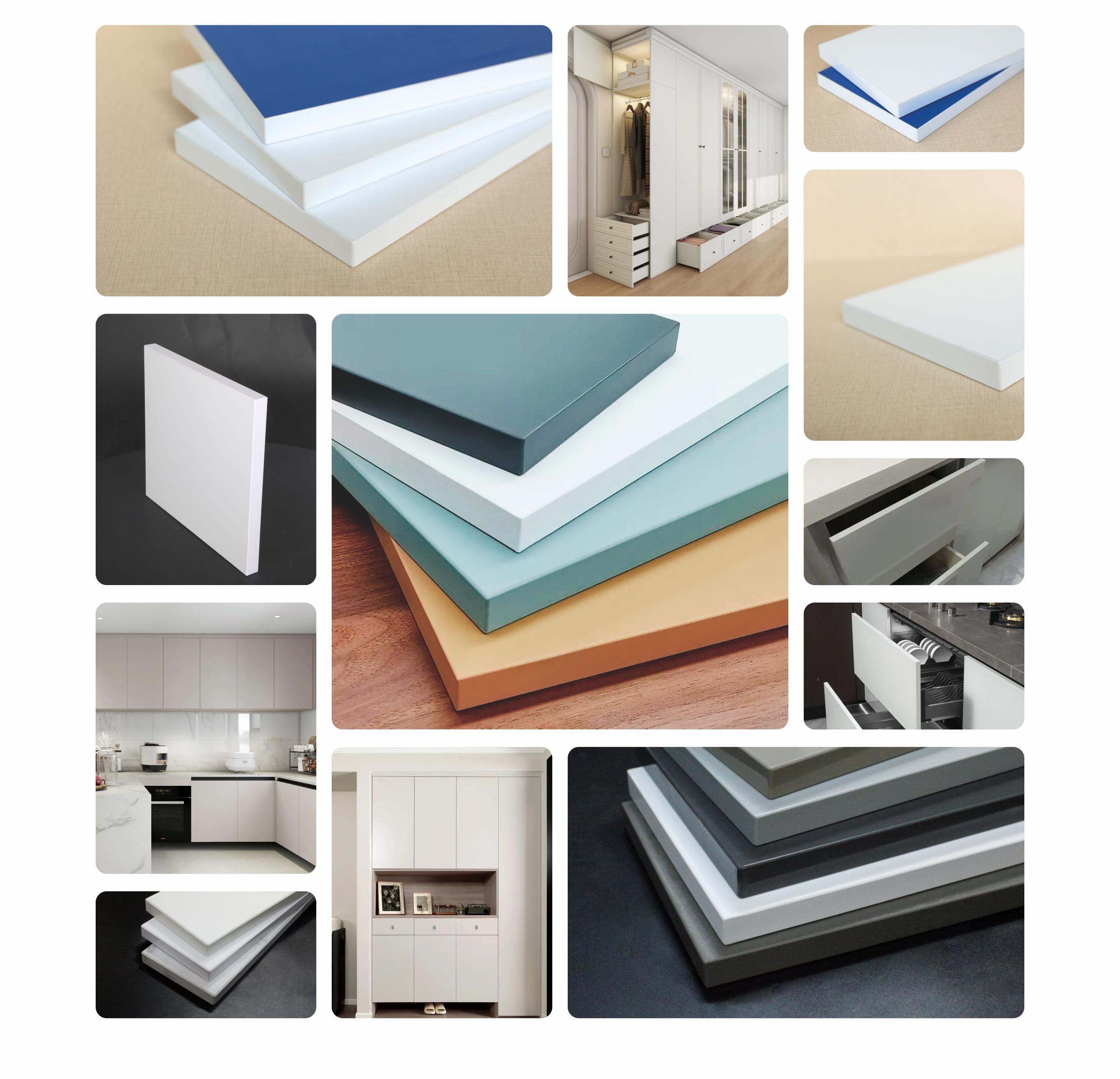

Various artificial boards such as density boards, particle boards, multi-layer boards, aluminum honeycomb boards, etc.;

batch customized furniture such as office furniture, cabinets, bathroom cabinets, etc.

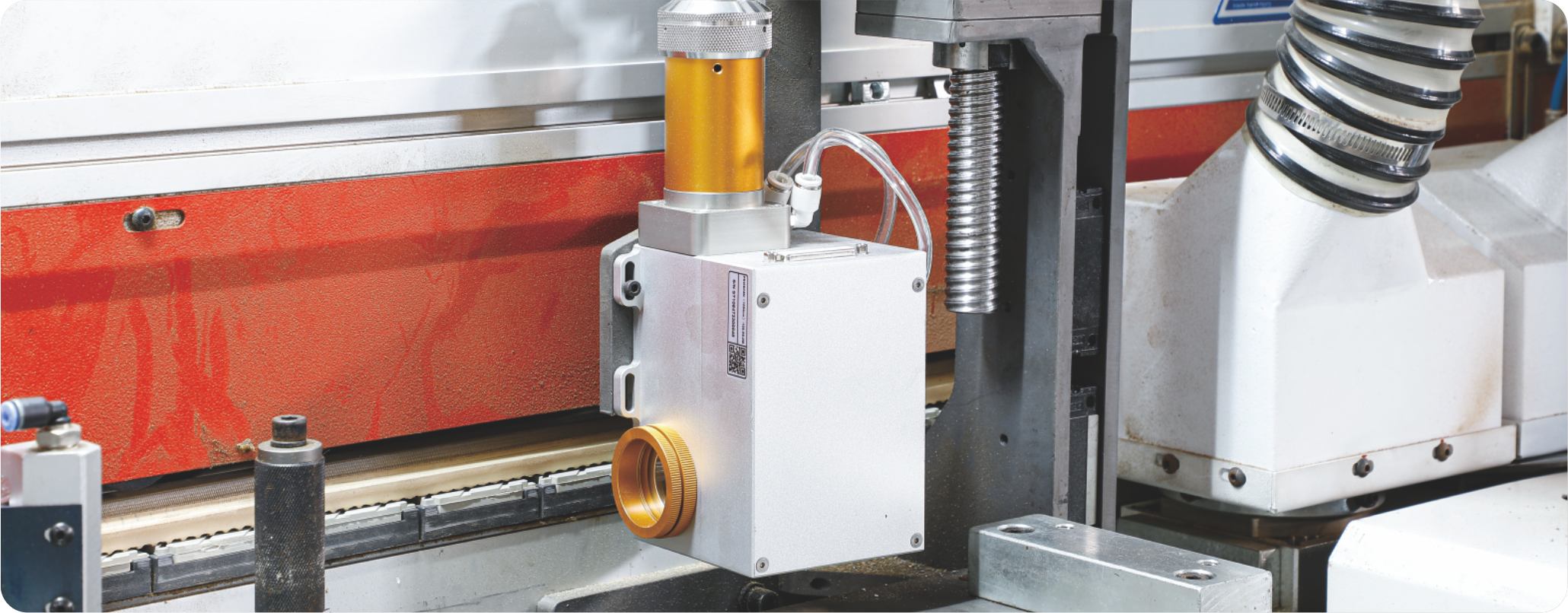

Laser edge banding

1.Using high-energy rectangular laser spot welding to seal the edge strip, the rectangular spot focuses stably.

2.'0' glue line, tightly sewn, one-piece molding with high aesthetic value.

3.High adhesion, sturdy edge banding without detachment, waterproof and moisture-proof, more durable.

4.Good sealing performance, maximally sealing formaldehyde inside the board to reduce air pollution.

Intelligent control device

21 inch industrial touch screen, one click start, easy to operate Simple human-computer interaction, easy to get started with with simple training.

PUR non cleaning glue pot

Can accurately heat PUR hot melt adhesive to the appropriate working temperature to ensure the performance and fluidity of the adhesive.

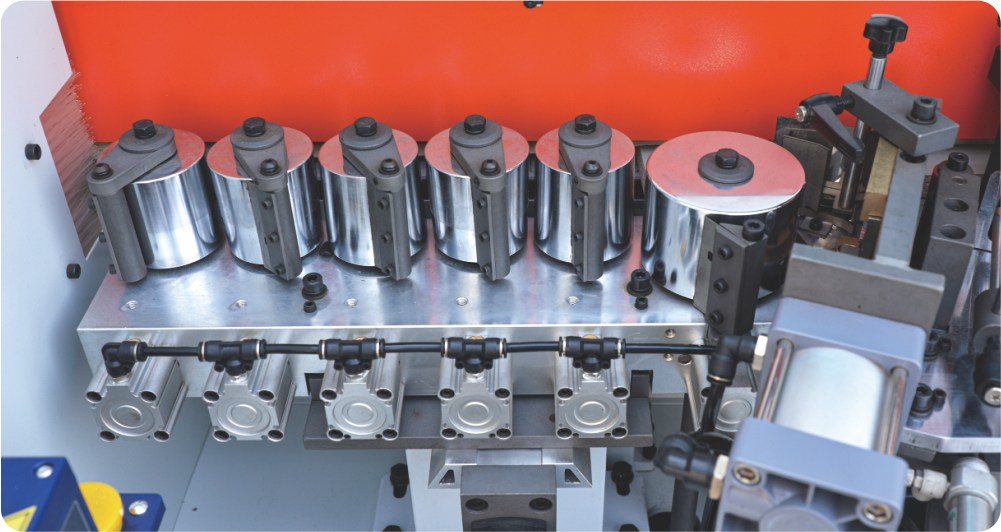

Six wheel pressure sticker

Six steel wheels prevent the edge tape from floating up and down and deviating. Multiple points are closely pressed to ensure a stronger bond between the edge banding tape and the board.

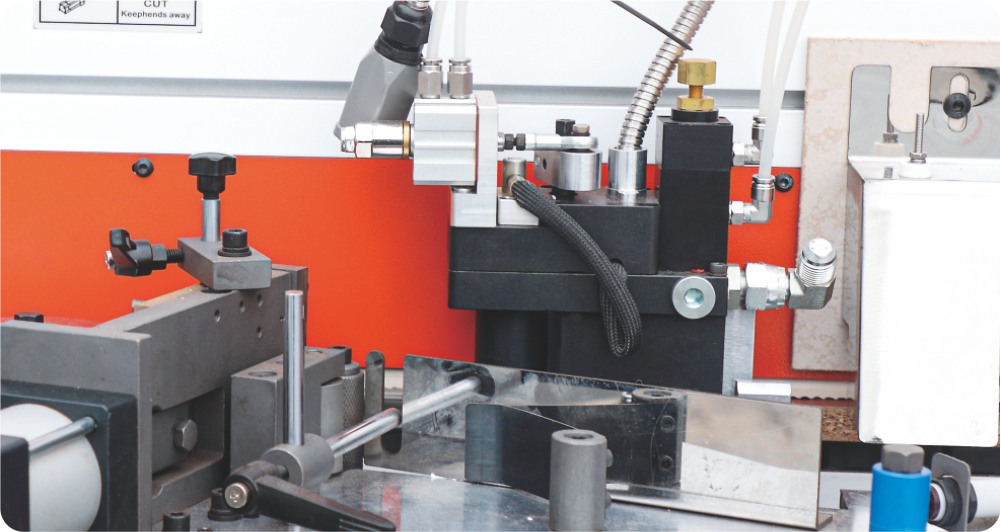

Front and back cutting

Real time scanning of sheet edges with four corner contour tracking,fast and accurate,Trim the edge banding to a right angle and shape it into a circular arc.