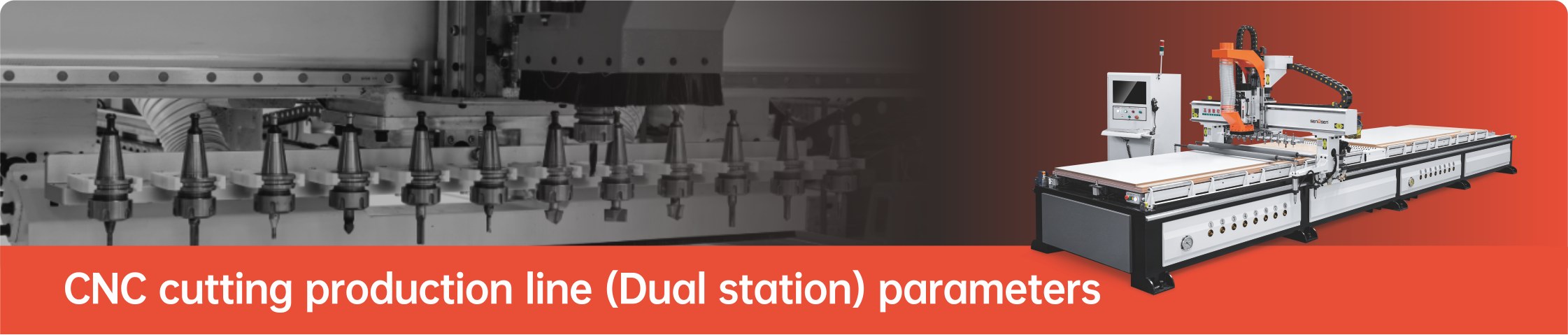

The integrated high-strength gantry body and dual station design achieve eficient and uninterupted production. The straight row tool changing magazine comes standard with 12 knives, which can quickly complete various processes such as cuting, drling, loting, miling, etc, it is compatible with multiple disassembly software and is an efficient tool for panel furniture production.

|

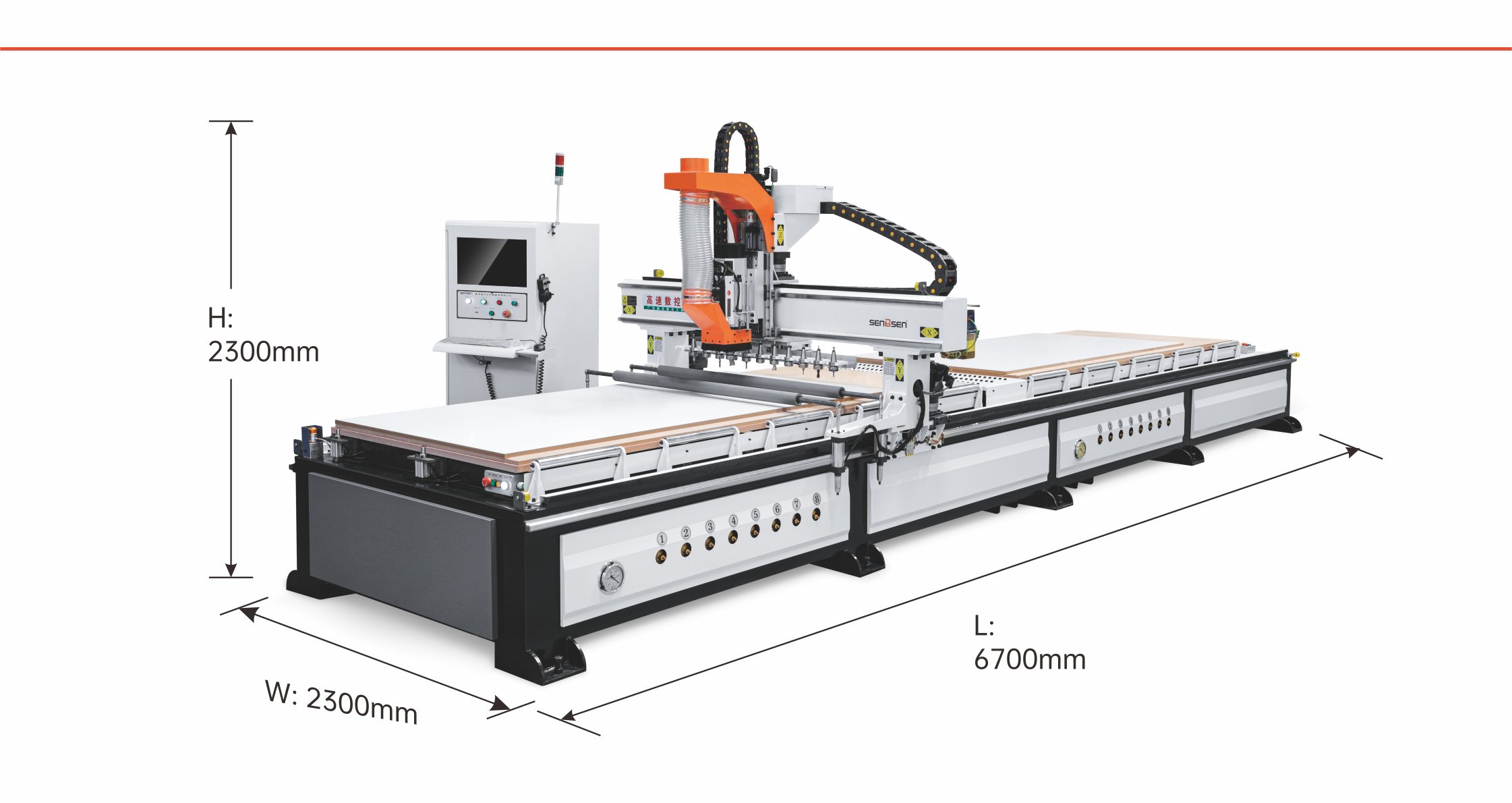

Model |

SBS - H9 - 12E CNC cutting production line (Dual station) |

|

Processing Size |

2440/2800*1220mm |

|

Material Processing Speed |

8 - 20m/min |

|

Spindle Power |

9.0kw Air cooled spindle |

|

Vacuum Pump Power |

11kw |

|

Spindle Speed |

18000r/min |

|

Total Power |

22kw |

|

Traveling Speed |

65 - 80m/min |

|

Overall Dimension |

6700*2300*2300mm |

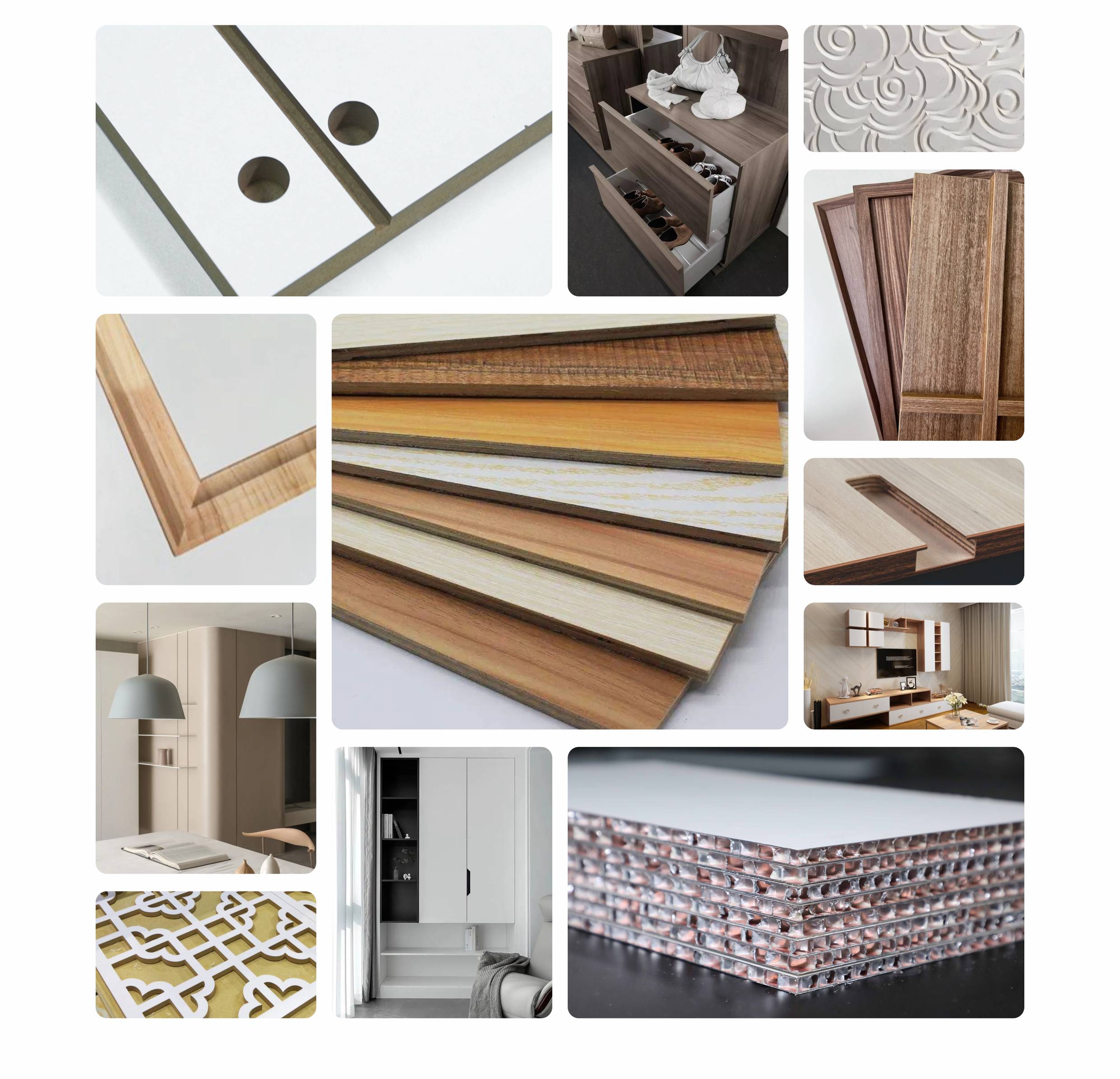

The machine can automaticaly complete the labeling, driling, slotting, cuting, and cuting of the board as an integrated procesing equipment. No need for manual flipping, double-sided punching and slotting can be completed in one go.

9KW automatic tool changing spindle(12 in-line tool library)

1. 9KW air-cooled spindle motor, no need to wait for tool change time, fast processing, higher eficiency.

2. 12 straight row knife storage, muliple knives can be freely switched to meet processes such as drlling, slotting, miling, canving, cuttingand three in one invisible parts. Multiple shapes can be completed in one go.

3. Dust free vacuum hood reduces the wear and tear of cutting tools caused by dust, ensuring dust-free cutting.

Dual station countertop

Two workstations are used alternately for processing, reducing idle time and achieving non-stop continuous processing, greatly improving production efficiency.

Pneumatic feeding sucker

Vacuum suction cup suction plate loading, stable loading,convenient and fast, eliminates manual lifting of the plate,and saves labor costs.

Pneumatic rubber roll (optional)

For processing narrow or irregular plates, it is not afraid of plate deformation, does not run off the plate, and has high processing accuracy.

Auxiliary feeding roller

Easy loading, avoiding collisions and scratches caused by manual loading and unloading, improving processing safety and efficiency.