As an innovative solution in the field of whole house customization, the door wall cabinet integrated machine. By integrating the three core elements of doors, wall panels, and cabinets, we achieve a deep integration of functionality,aesthetics,and efficiency.

|

Model |

KHM - 610 Door wall cabinet integrated machine |

|

X - axis working stroke |

3050mm |

|

Y - axis working stroke |

120mm |

|

Z - axis working stroke |

70mm |

|

High speed spindle |

3.5kw*3 + 6kw*1 + 6kw*1 (automatic tool change spindle) |

|

Frequency changer |

4kw |

|

Overall dimension |

4900*1400*1300mm |

|

Weight |

About 1000kg |

|

Worktable size |

3200*500mm |

|

Attached stage |

400*600mm |

Satisfy processes such as door lock holes, hinge holes, begonia angles, 45 degree beveled edges, mortise and tenon joints,

blinds, light cable trays, and handle free design.

Multi functional machining spindle

1.Multi functional five spindle, paired with a 6KW automatic tool changing spindle.

2.Quickly and automatically change tools according to process requirements to improve production efficiency.

3.Suitable for the processing needs of panel furniture door panels, wardrobe door panels, wall panels and other panel components.

4.One machine is versatile and can meet various process reauirements such as door lock holes, hinge holes, rabapple angles, and handle free.

Intelligent control device

The interface is intuitive and clear, with multiple built-in processingmodules,Quickly switch processing technology.

Six knife magazines

Equipped with six automatic knife changing tool magazines,Quick automatic tool change.

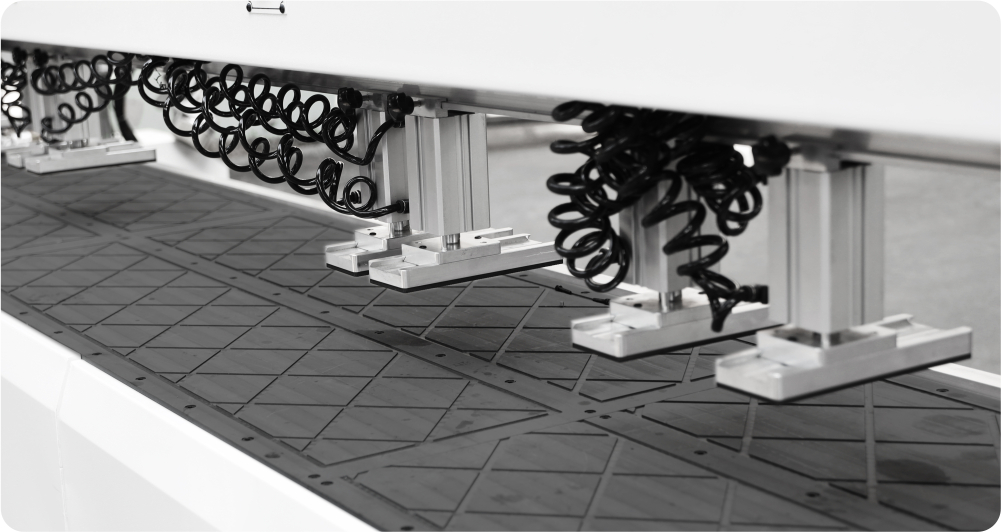

Material pressing device

Stabilize the pressing material, prevent the board from moving during the processing, and ensure processing accuracy.

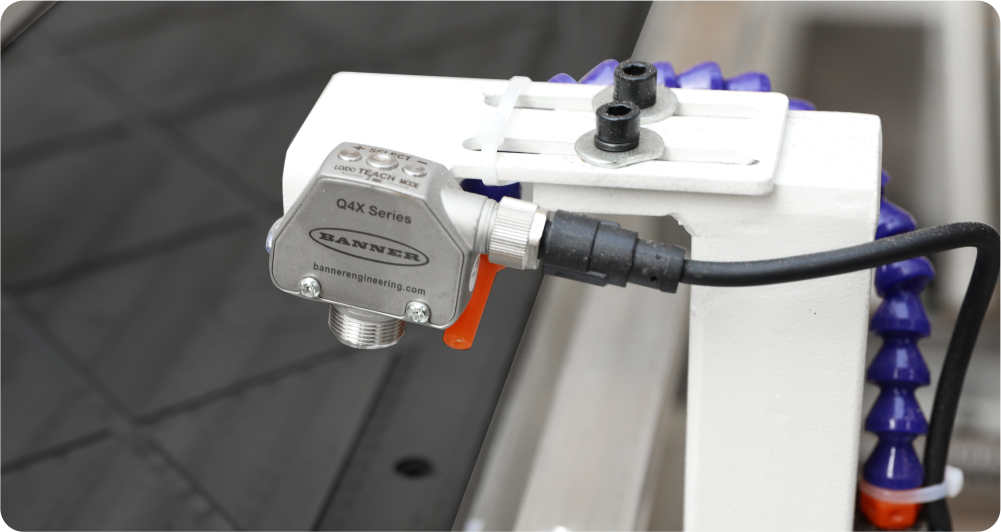

Automatic measurement

Laser probe, fast positioning, automatic measurement of the length of the board.