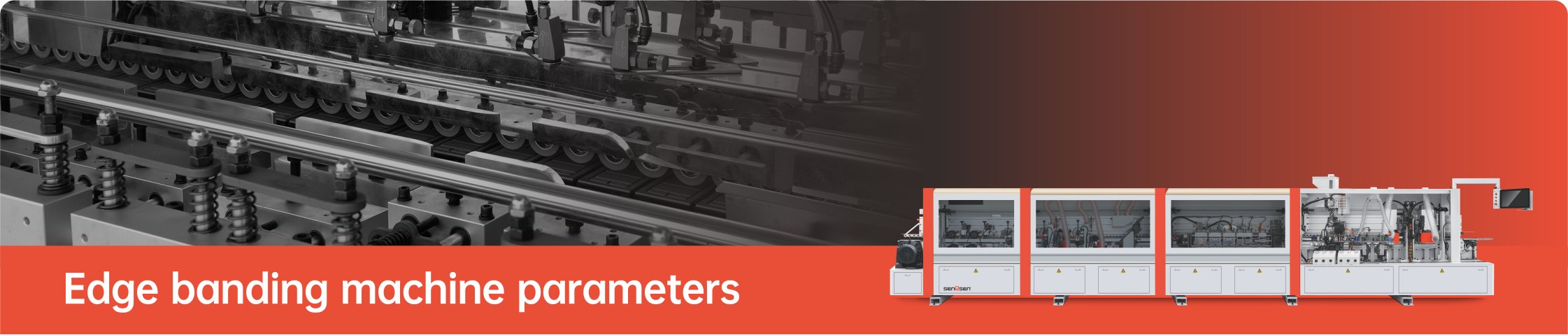

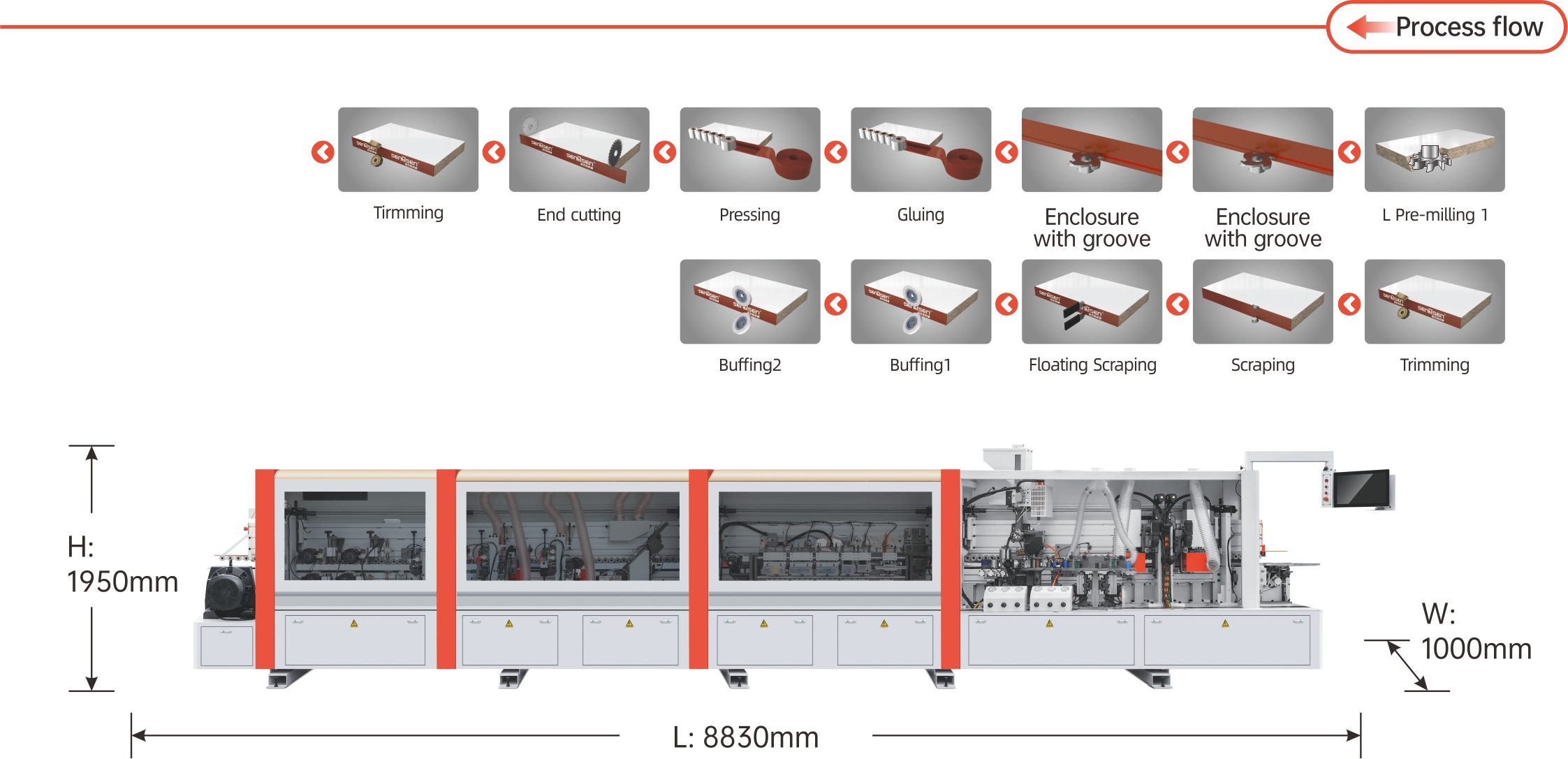

The entire edge banding process is strictly controlled, with L-shaped forming miling>edge banding slotting 1>edge banding sloting 2>adhesive bonding>forming pressure bonding>alignment>Rough polishing>Fine polishing>Edae scraping>Flat scraping>Polishing 1>Polishing 2;After multiple rounds of quality inspection and repeated debugging,we have achieved smooth and firm edge sealing with perfect details, providing a solid quarantee for furniture quality.

|

Model |

SBS-L602 Fully automatic edge banding machine for parent-child doors |

|

Sheet length |

>120mm |

|

Input voltage |

380V |

|

Sheet width |

>40mm |

|

Input frequency |

50HZ |

|

Plate thickness |

18 - 60mm |

|

Air pressure |

0.6Mpa |

|

Sealing tape thickness |

0.6 - 2mm |

|

Total power |

52.9kw |

|

Feed rate |

10 - 22min |

|

Machine dimensions |

8830*1000*1950mm |

It can seal sub doors, mother doors, T-shaped edges, straight edges, etc,integrating multiple processes to ensure high-quality and aestheticaly pleasing edge sealing of door panels.

L-edge Banding

Through modular cuterhead design, the blade can quickly switch to horizontal or vertical slots to meet cutting needs in different directions Processing of corugated marks, burs, or non verticality that may be left behind after initial processing with a panel saw or cutting saw

Edge banding grooving

According to the preset angle, groove the inner side of the edge banding to facilitate bending and pressing, ensuring the quality of pasting and preventing edge bursting.

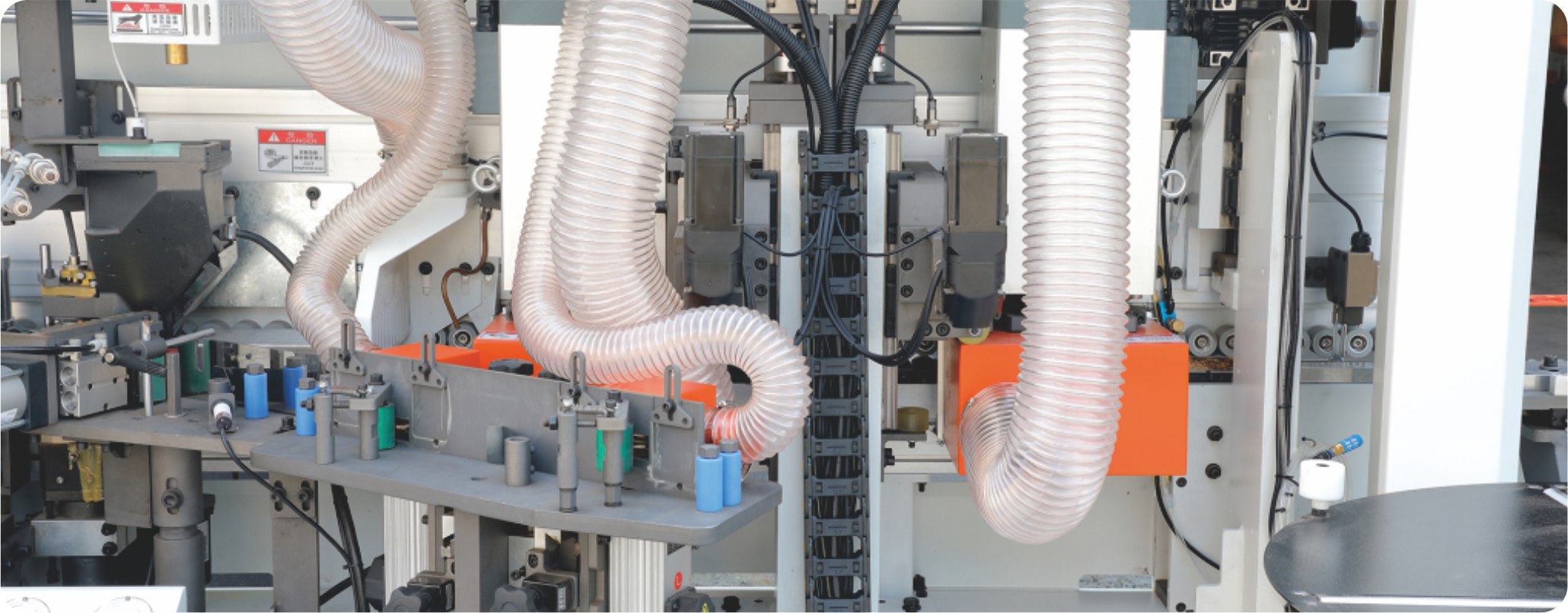

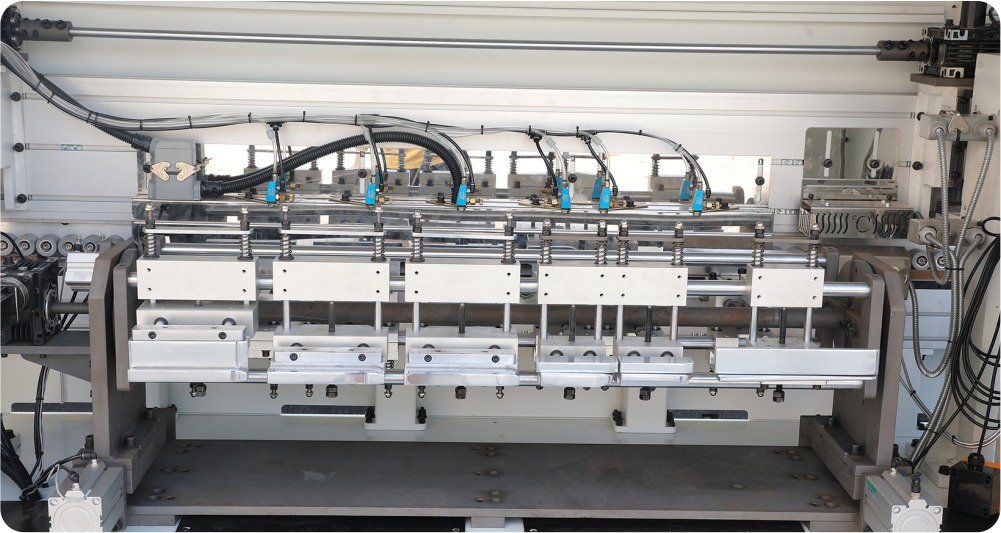

Lamination molding

By using a cylinder to push the pressure wheel, the edge banding is tightly adhered to the board, and a multi-stage pressure wheel design is adopted to achieve uniform force and improve the bonding effect

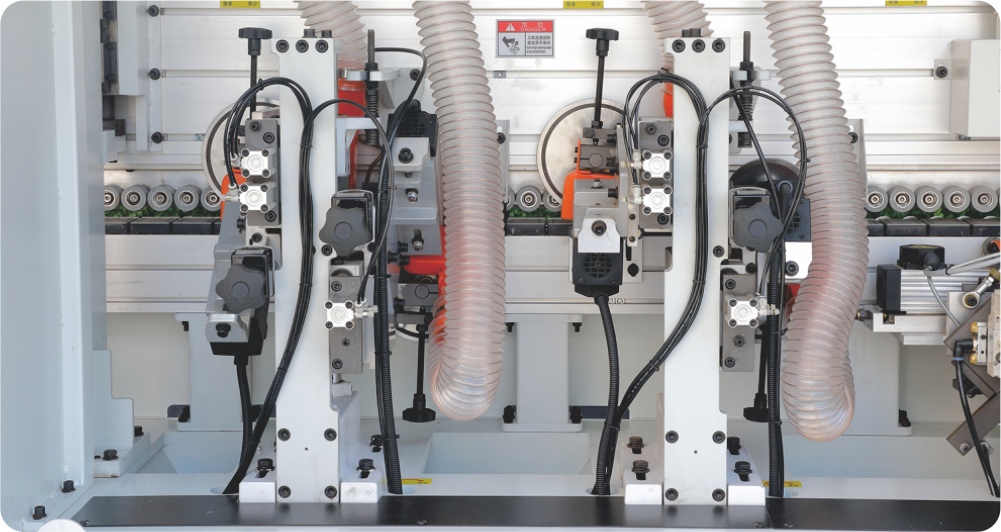

End trimming

Used for quick cutting of excess edge banding at the front and rear ends of the board to ensure flatness of the cut surface,effectively eliminating chipping, burrs, etc.

Edge Trimming

By using high-speed motors and automatic tracking technology,the excess edge banding on both sides of the edge banding is smoothed out.