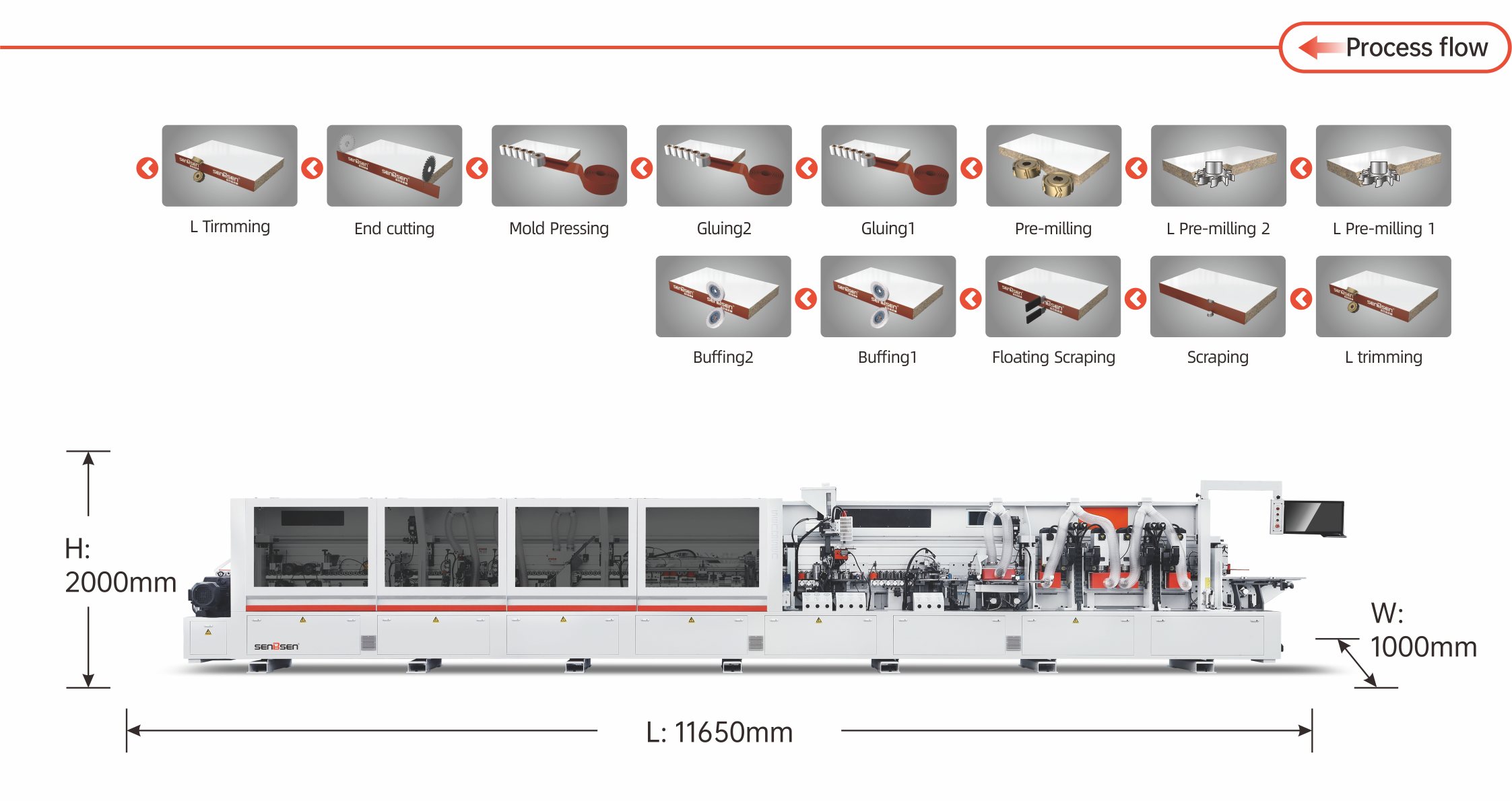

The entire edge sealing operation is stictly controled, including l pre-miling 1 > l pre-miling 2 > pre-miling > gluing 1 > qluing 2> mold pressing >end cuting > l tirmming > l tirmming > scraping > floating Scraping > bufing1 > bufing2 ; After muliple quality checks and repeated debugging,the edge seal is flat and firm.

|

Model |

SBS-L802 Fully automatic edge banding machine for parent-child doors |

|

Sheet length |

>120mm |

|

Input voltage |

380V |

|

Sheet width |

>40mm |

|

Input frequency |

50HZ |

|

Plate thickness |

10 - 60mm |

|

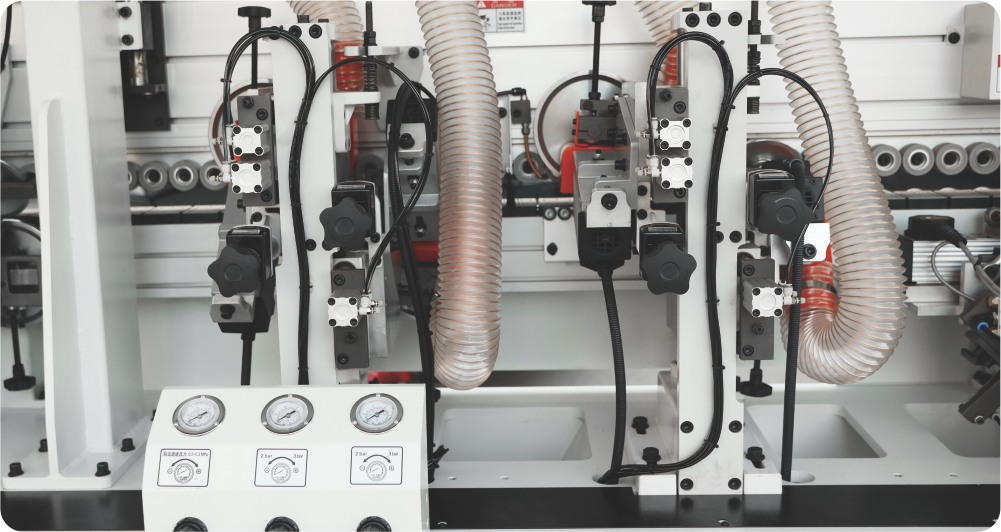

Air pressure |

0.6Mpa |

|

Sealing tape thickness |

0.3 - 3mm |

|

Total power |

73.8kw |

|

Feed rate |

18 - 22min |

|

Machine dimensions |

11650*1000*2000mm |

Varilous artificial boards such as density boards, paticle boards, multi-layer boards, aluminum honeycomb boards, etc.,batch customized furniture such as office furniture, cabinets, bathroom cabinets, etc.

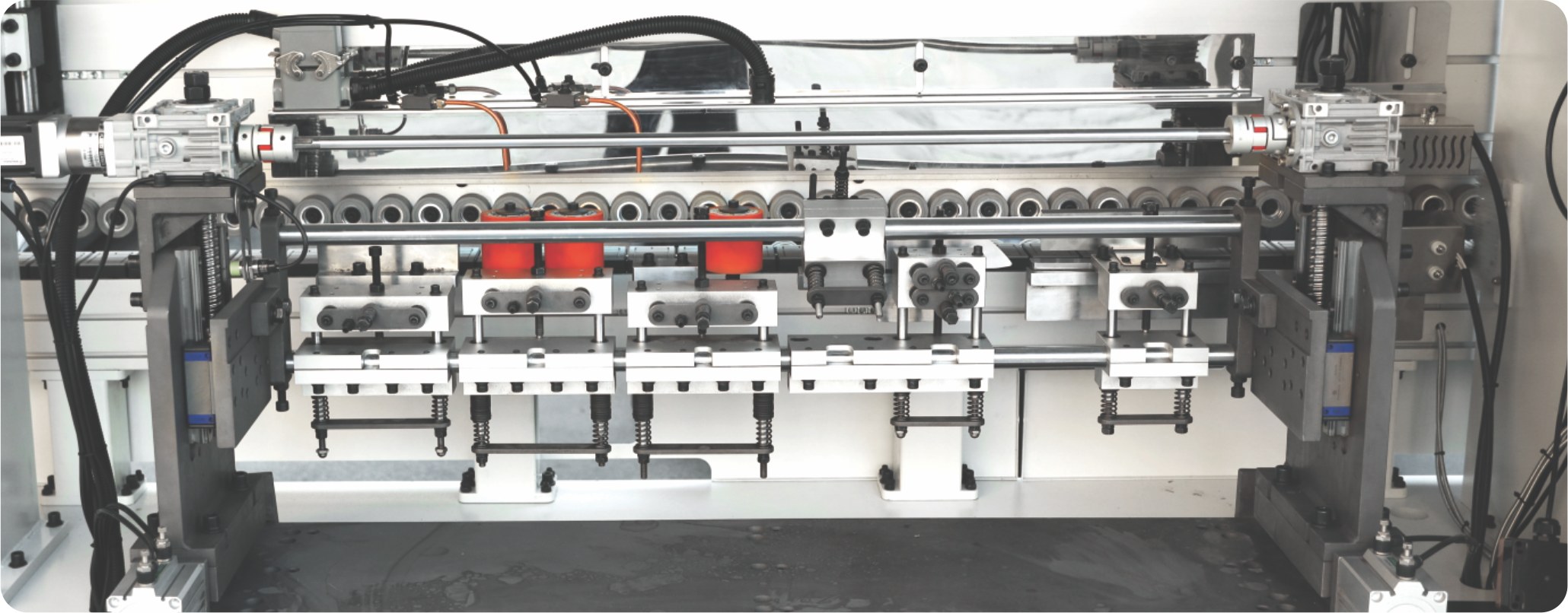

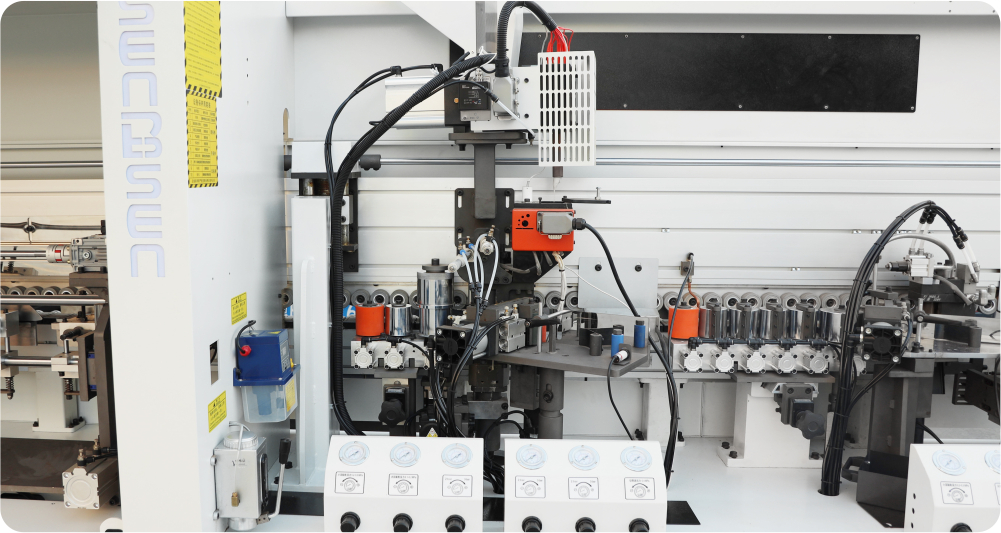

Servo molding pressure sticker

Multiple independent pressing modules, according to the servo forming miling cuter process, can be adjusted with one click inkage to achieve precise pressing of difterent edge structures and shapes of the mother doo, ensuring even and firm adheslon between the edge banding and the workpiece edge.

Profile Tracing

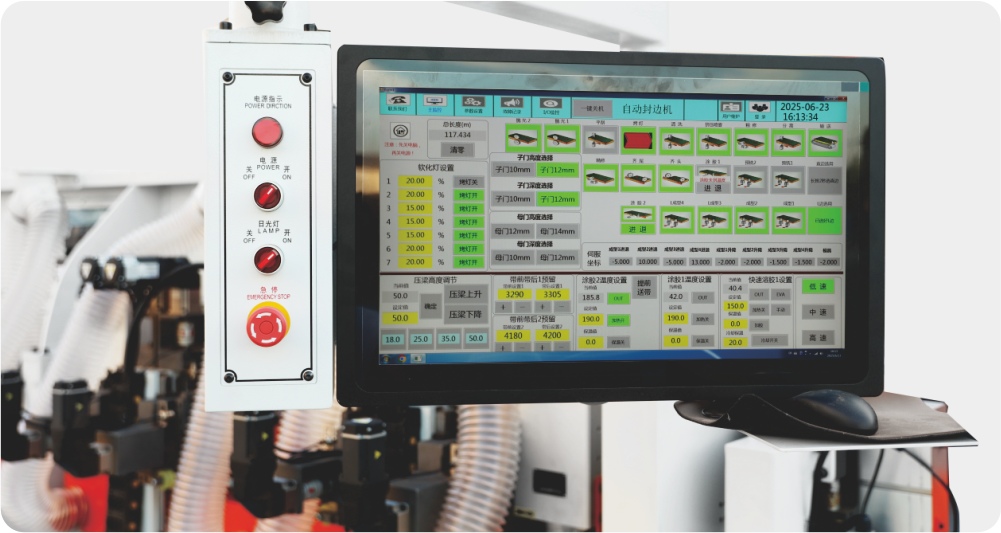

Huichuan control system, one click switch between sub/main door process requirements.Simple human-computer interaction, easy to get started with with simple training.

Glue pot+quick sol

The glue box automatically extracts glue, heats up automatically and seals the edges with glue without waiting. it quickly dissolves and precisely controls the glue.

L-edge Banding

Through modular cutterhead design, the blade can quickly switch to horizontal or vertical slots to meet cutting needs in different directions.

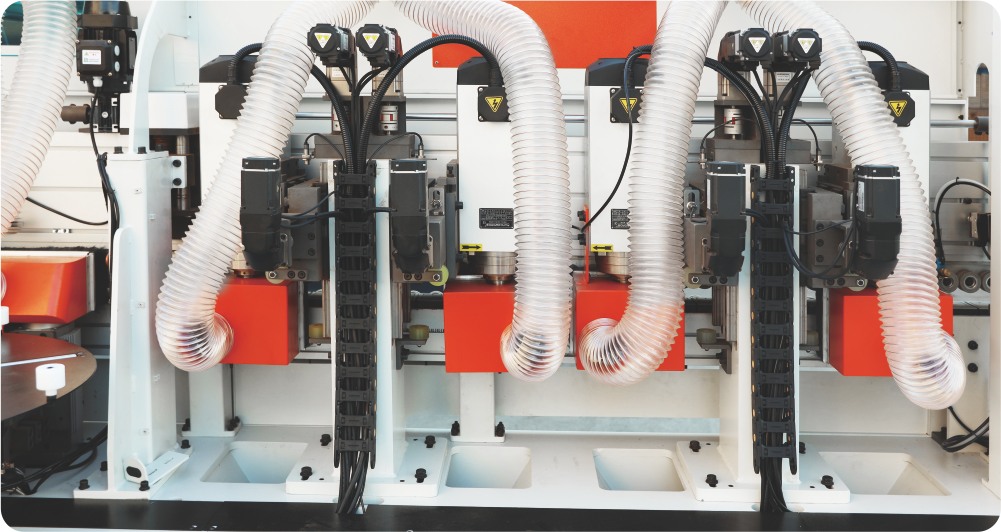

Edge Trimming

By using high-speed motors and automatic tracking technology, the excess edge banding on both sides of the edge banding is smoothed out.