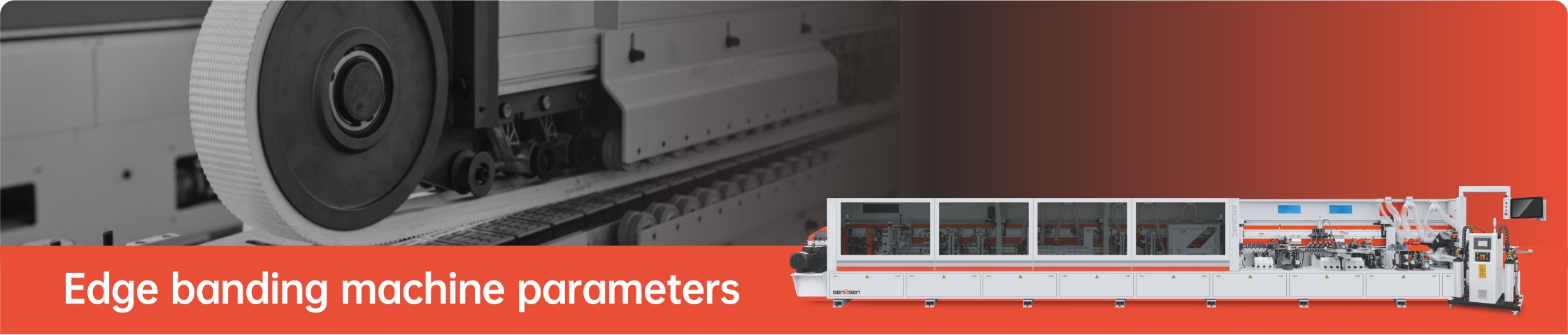

Strict control throughout the edge sealing process, including pre miling of beveled edges>pre miling of straight edges>groove engraving on edge strips>PUR coating>oblique and straight pressure pasting>PUR coating>pressure pasting Double rail alignmentb>rough repair>fine repair>four blade tracking>edge scraping 1>edge scraping 2>flat scraping>polishing and waxing>polishing 1>polishing 2; After multiple rounds of quality inspection and repeated debugging,we have achieved smooth and firm edge sealing with perfect details, providing a solid quarantee for furniture quality.

|

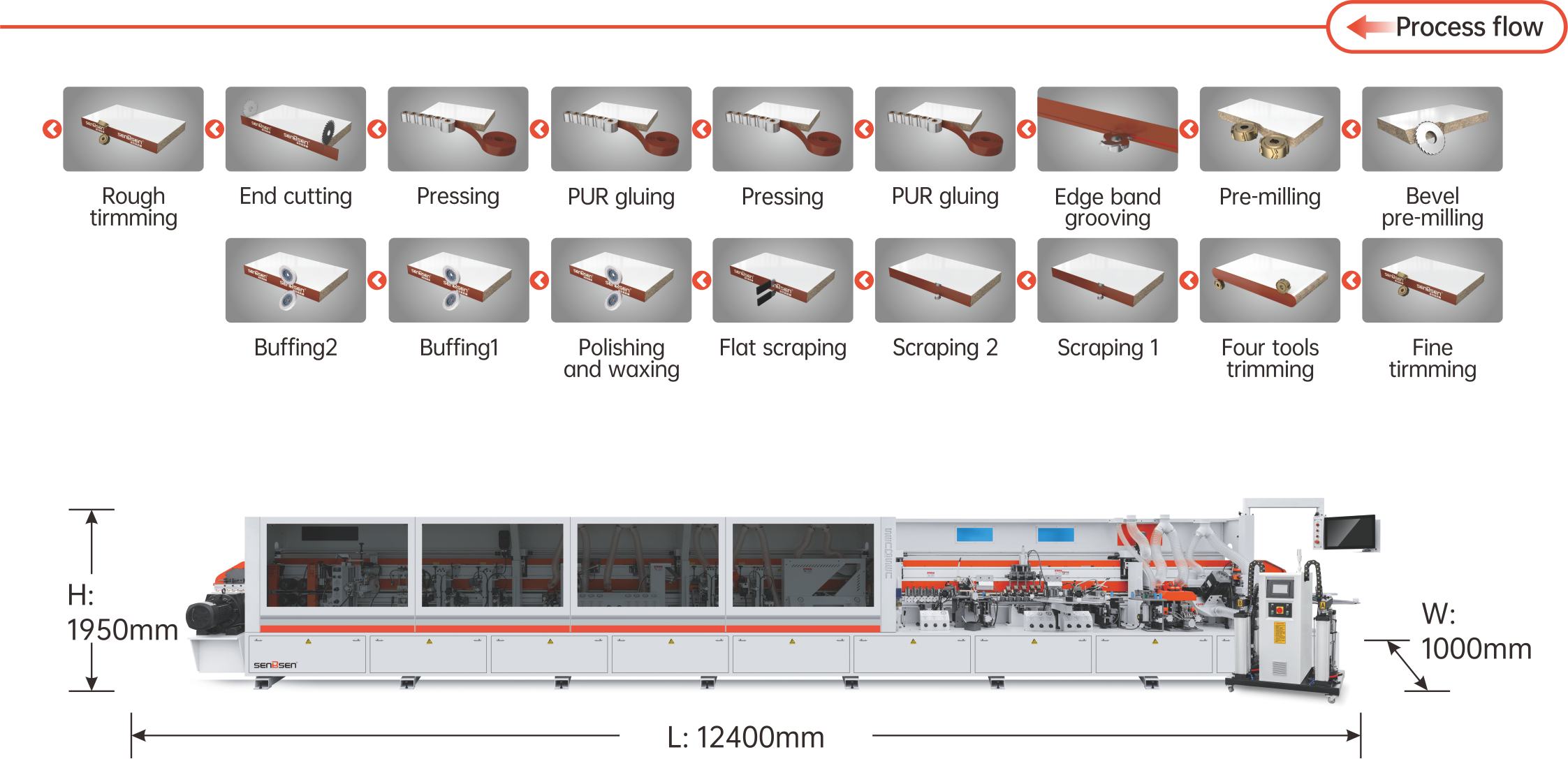

Model |

SBS-MLX1000 Aluminum-Wood Bevel & Straight Edge Banding Machine |

|

Feed speed |

26m/min |

|

Edge band thickness |

0.3-3mm |

|

Plate length |

≥120mm |

|

Plate width |

≥50mm |

|

Sheet thickness |

10 - 60mm |

|

Input voltage |

380V |

|

Input frequency |

50HZ |

|

Air pressure |

0.6Mpa |

|

Total power |

33.7kw |

|

Machine size |

12400*1000*1950mm |

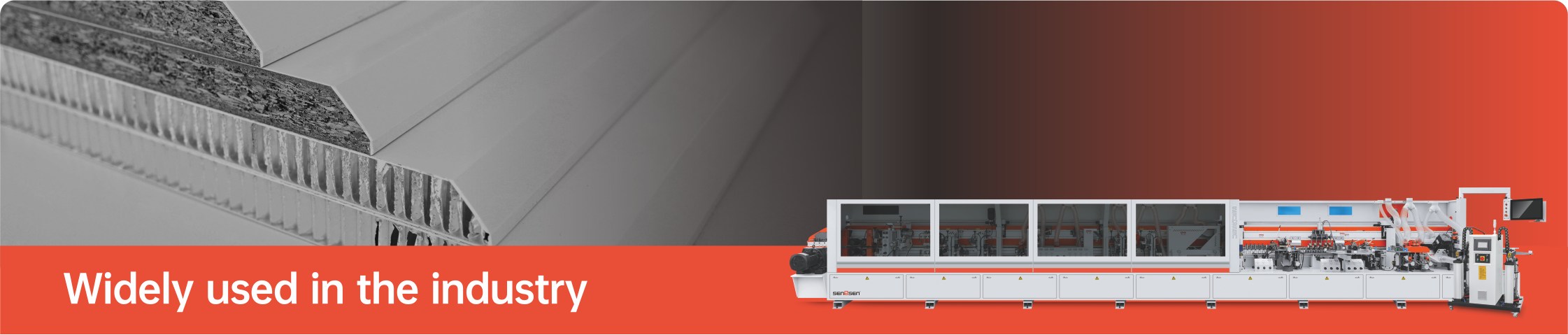

Various artificial boards such as density boards, particle boards, multi-layer boards, aluminum honeycomb boards, etc.;

batch customized furniture such as office furniture, cabinets, bathroom cabinets, etc.

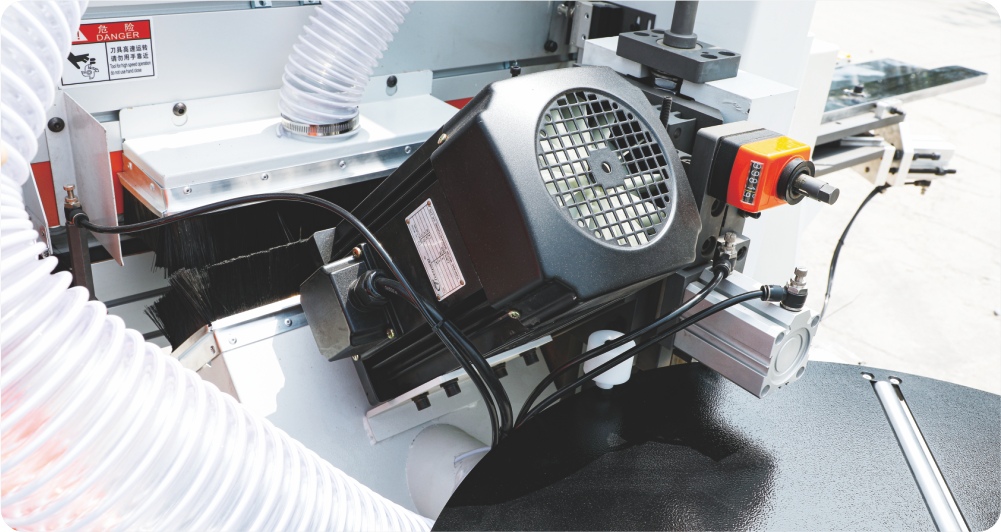

Double guide end cutting

1.The dual rall design avoids the problem of delayed handling of both head alignment and reaction alignment with a single rall.

2.Through precise double linear guide rail motion, automatic tracking by the model and fast cuting by high-speed motor.

3.Ensure that the cutting surface is flat and smooth, and quickly cut off the edge banding at the beginning and end of the workpiece.

4.Double rail 45 degree head alignment design, more precise, efficient, and reduces the risk of collision.

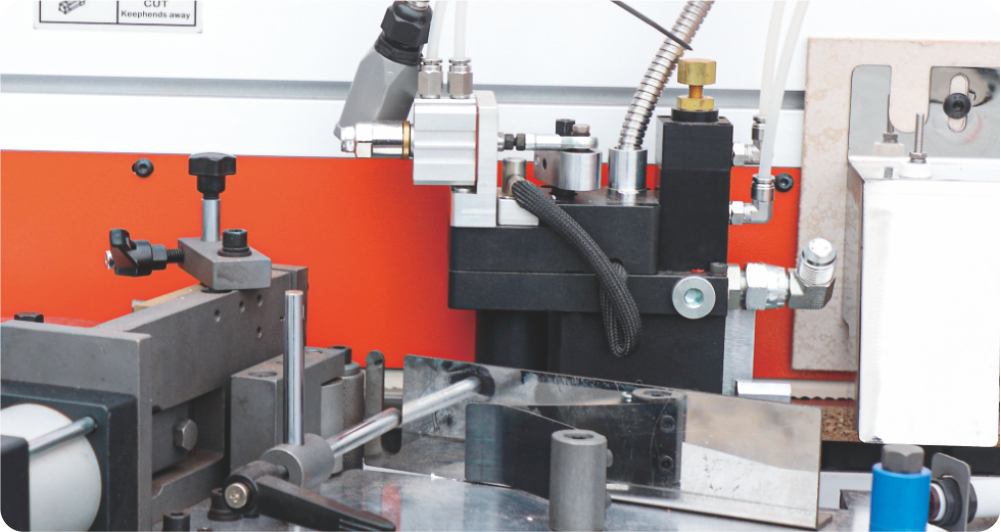

Diagonal sawing

Milling the straight edge to the desired angle at once to ensure a smooth and burr free cutting surface.

PUR non cleaning glue pot

Can accurately heat PUR hot melt adhesive to the appropriate working temperature to ensure the performance and fluidity of the adhesive.

Oblique edge pressure sticker

Multi row cylinder linked pressure wheel,Apply vertical pressure to the beveled edge sealing tape.

Polishing and waxing

Wax blocks evenly cover the surface of the edge banding,forming a protective film.