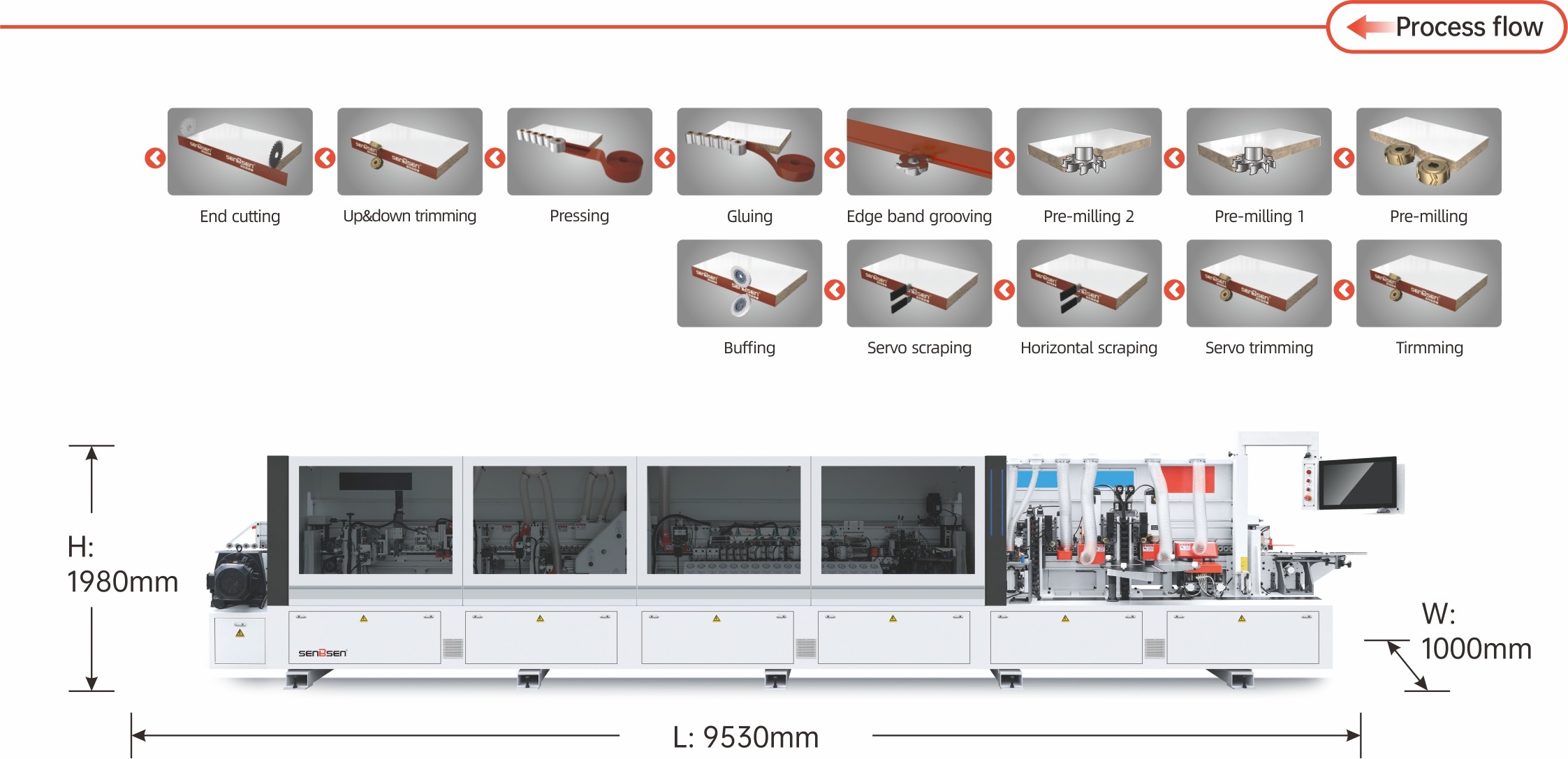

The entire edge sealing operation is strictly controlled,including pre-miling 1 > pre-miling 2 > edge band grooving > gluing > pressing >up & down trimming > end cutting > tirmming > servo trimming > horizontal scraping > senvo scraping > bufing ; After multiple quality checksand repeated debugging, the edge seal is flat and firm.

|

Model |

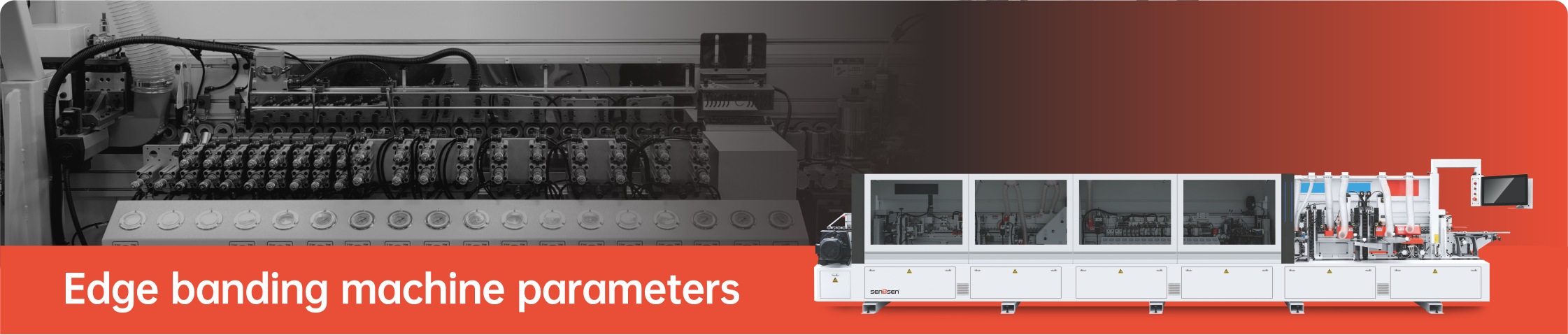

SBS - S700 Handle - free Profile Shape Edge Banding Machine |

|

Sheet length |

200mm |

|

Sheet width |

120mm |

|

Plate thickness |

Straight edge: 18mm; When J - shaped, reserve > 5mm |

|

Edge banding thickness |

Straight edge: 0.6 - 1.5mm; J - type: 0.5 - 0.8mm |

|

Feed rate |

0 - 22m/min |

|

Input voltage |

380V, 50HZ |

|

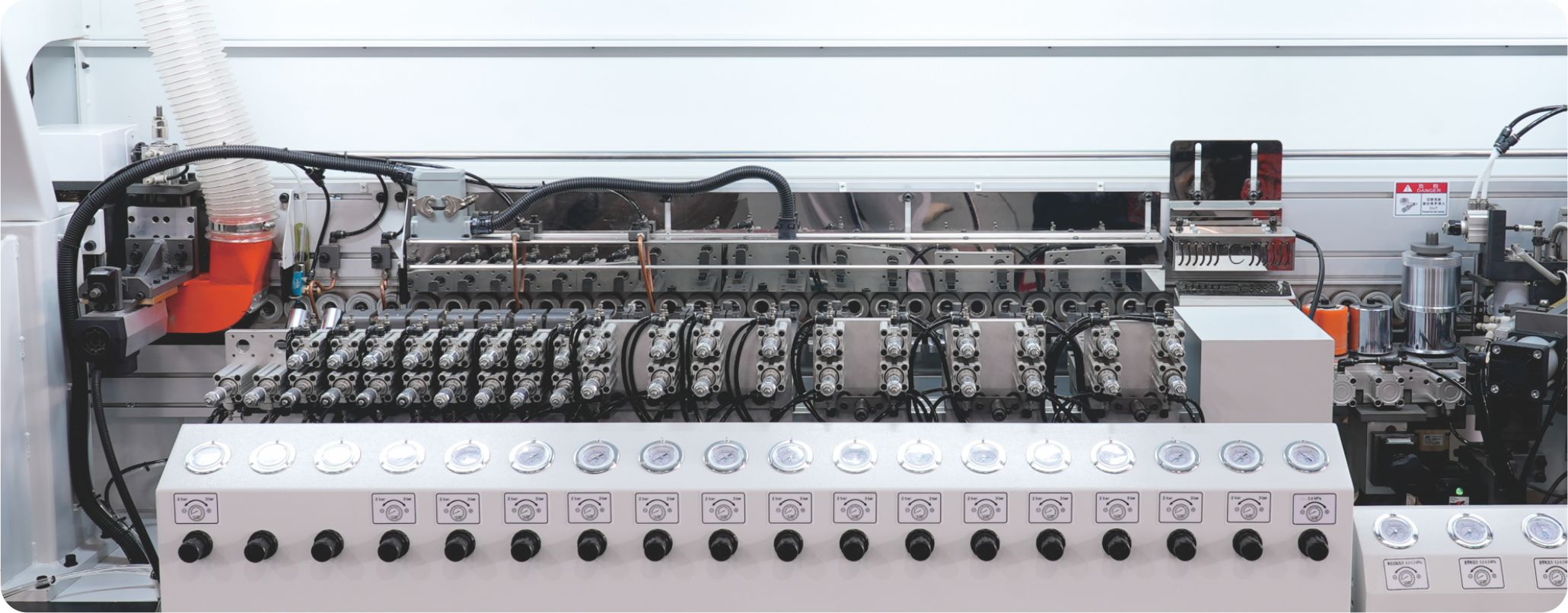

Air pressure |

0.6Mpa |

|

Total power |

62.8Kw |

|

Machine dimensions |

9530*1000*1980mm |

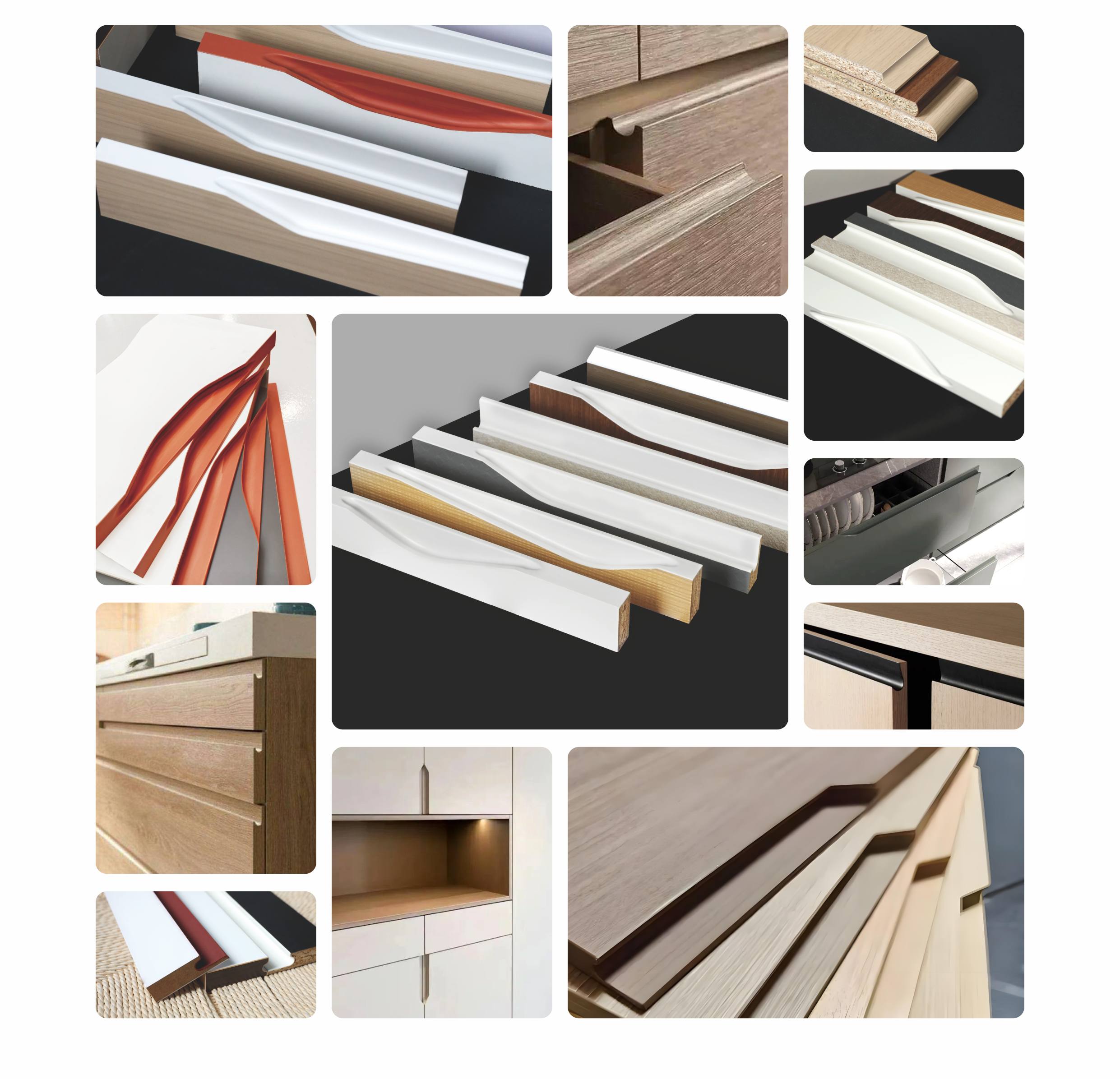

Various artificial boards such as density boards, particle boards, multi-layer boards, aluminum honeycomb boards, etc.;

batch customized furniture such as office furniture, cabinets, bathroom cabinets, etc.

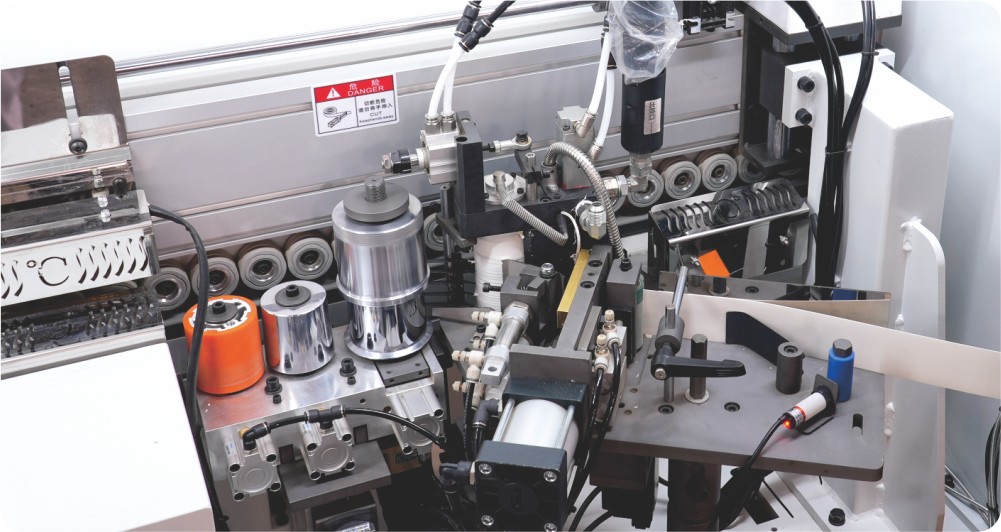

Forming pressing

1.The press wheel is pushed through the cylinder to fit the edge strip closely with the sheet;

2.The multi-stage pressing wheel design is adopted to achieve uniform stress and improve the bonding effect;

3.Make sure that the edge sealing surface of the sheet is perpendicular to the pressing wheel to reduce fitting deviation;

4.To meet the edge sealing needs of complex shapes such as arcs and special shapes.

Glue pot device

Photoelectric infrared sensor, controls the amount of glue residue, Evenly glue is produced and the edge sealing effect is better.

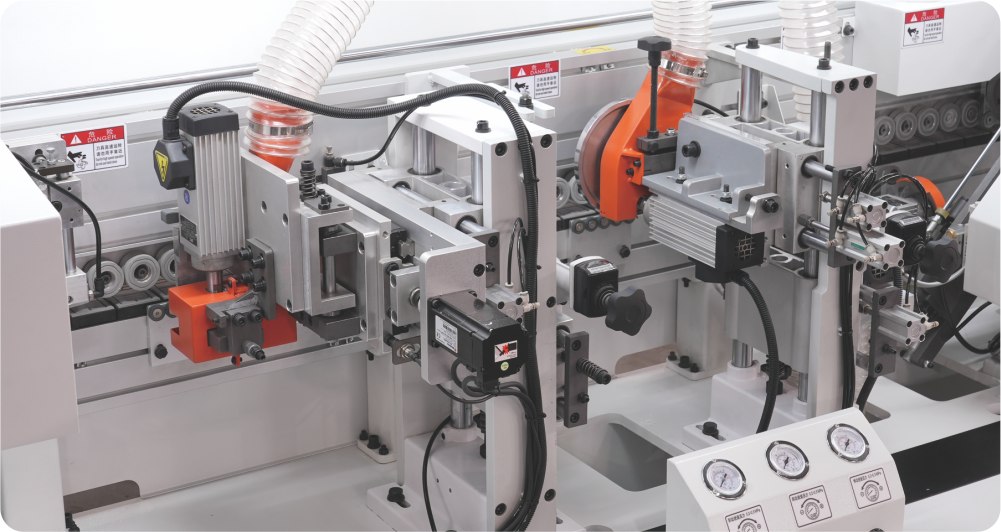

Servo trimming

Servo imitation refinement, following the irregular trajectory to create the upper and lower arcs of the edge banding according to the shape, resulting in a natural and beautiful effect.

Forming and milling device

3 sets of independent pre milling, servo control, high-power millingcutters, one click switching between different shapes for easy milling of various shapes such as j-shaped, C-shaped, water droplet, arc, etc.

Front and back cutting

Used to quickly cut off the excess edge sealing tape at the front and rear ends of the board to ensure the flatness of the cutting surface and effectively eliminate edge collapses, burrs, etc.