One click touch operation enables automatic positioning, feeding, and sawing of boards, After inputing size parameters, the system automatically generates a processing path with a maximum sawing thickness of 100mm and a maximum sawing length of 3200mm. it is widely used for sawing density boards, particleboard, MDF aluminum boards, solid wood boards, and other boards.

|

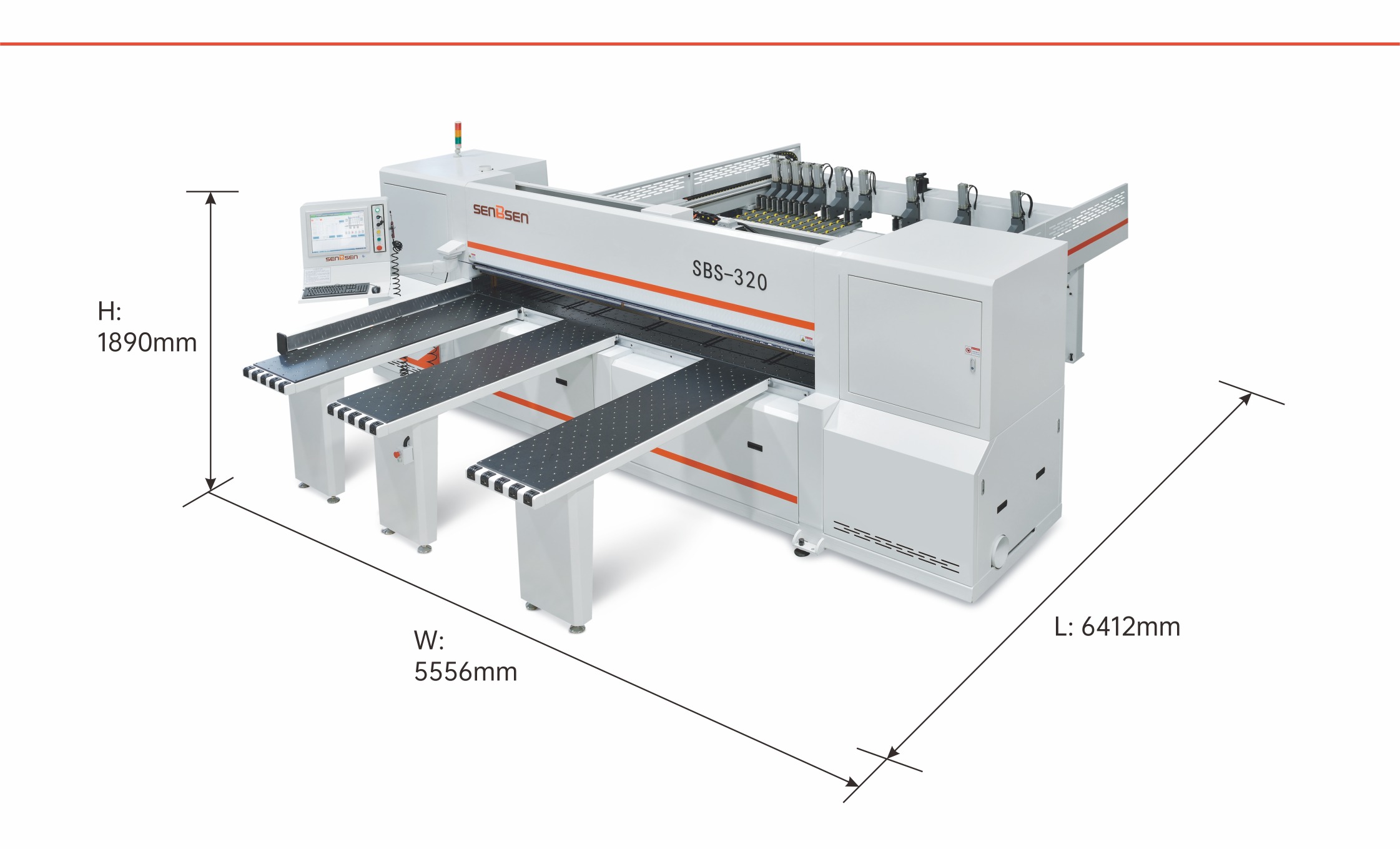

Model |

SBS - 320 Fully automatic CNC computer saw |

|

Processing size |

0 - 3200mm |

|

Main Speed |

0 - 80m/min |

|

Processing Thickness |

0 - 100mm |

|

Cutting Speed |

0 - 100m/min |

|

Max. Size |

3100*3200*100 |

|

Total Power |

15kw |

|

Power |

1.8kw |

|

Overall Dimension |

6412*5556*1890mm |

Various artificial boards such as density boards, particle boards, multi-layer boards, aluminum honeycomb boards, etc.,batch customized furniture such as office furniture, cabinets, bathroom cabinets, etc.

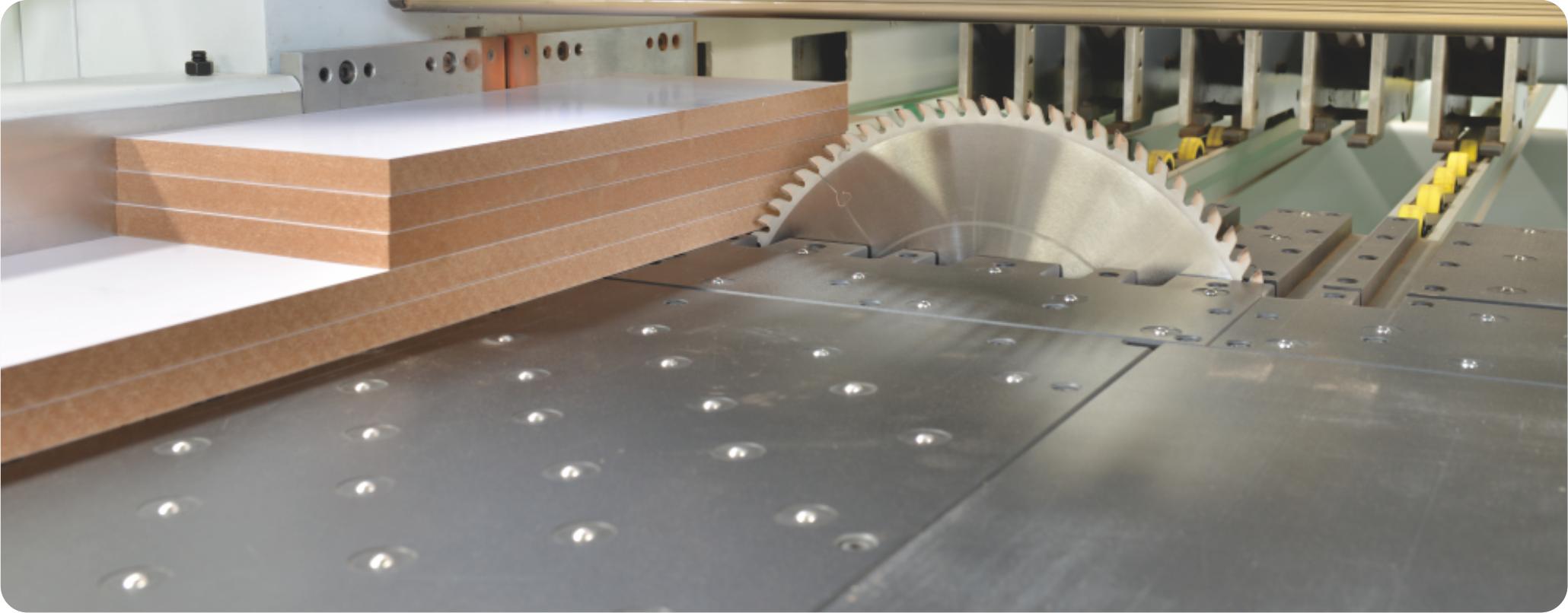

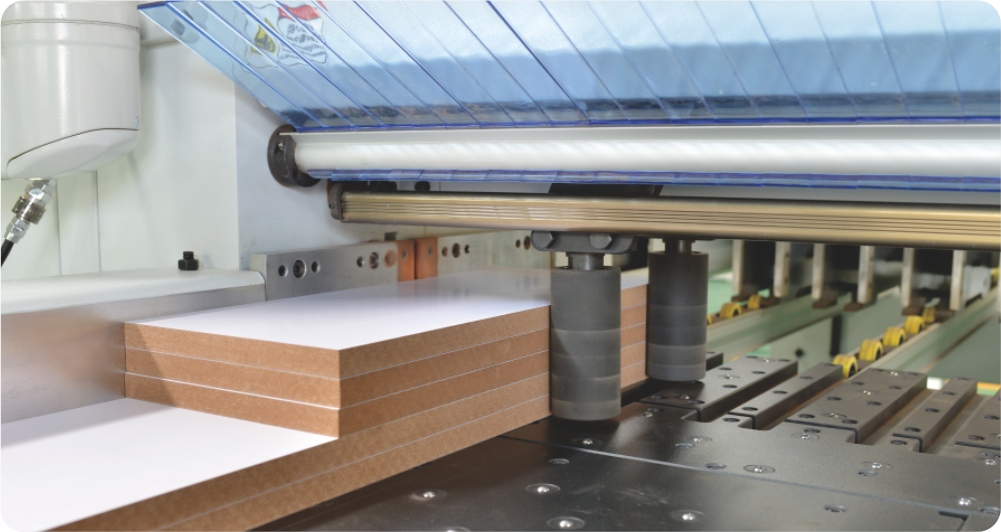

Mother child saw combination

1. The smallsaw cuts the groove first, and the large saw cuts it again to prevent edge breakage. The maximum sawing size is 3200mm.

2. Multiple boards can be stacked and cut at once, batch cutting, with a maximum sawing thickness of 100mm.

3. The mother and child saw blades are independently raised and lowered, and the cuting stroke is automatically positioned according to the thickness of the board, reducing idle time.

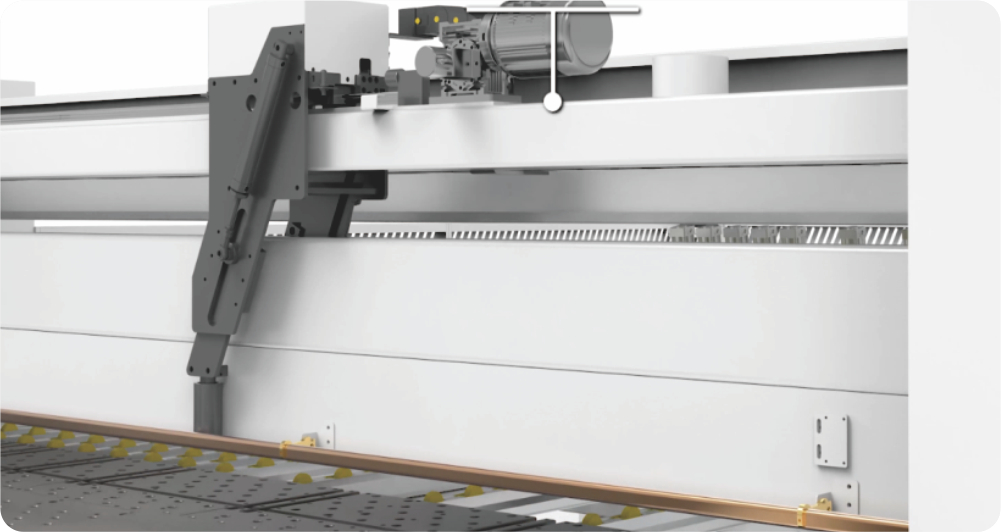

Automatic siding device

Lateral compression is applied to the board to save alignment time and achieve more precise processing of narrow and long boards.

Pneumatic feed grip

High precision servo feeding system, precise positioning, stable and reliable feeding, without damaging the board parts.

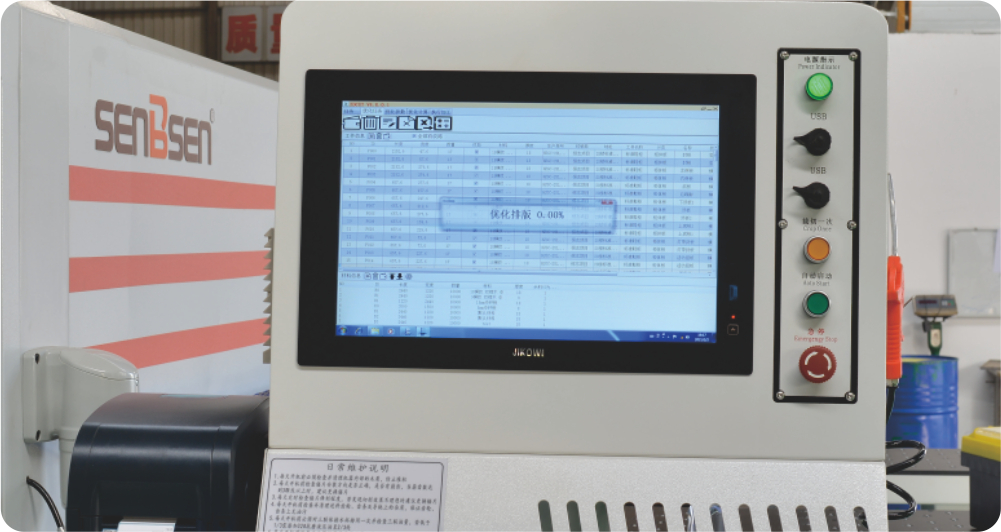

Intelligent control

PC computer control system, can be integrated with various disassembly software, has strong compatibility, intelligently optimizes layout,saves materials and reduces waste.

Pressure beam/saw blade lift automatic positioning

Accurately adjust the height of the pressure beam according to the thickness of the board, reduce the empty stroke, and improve the sawing efficiency.