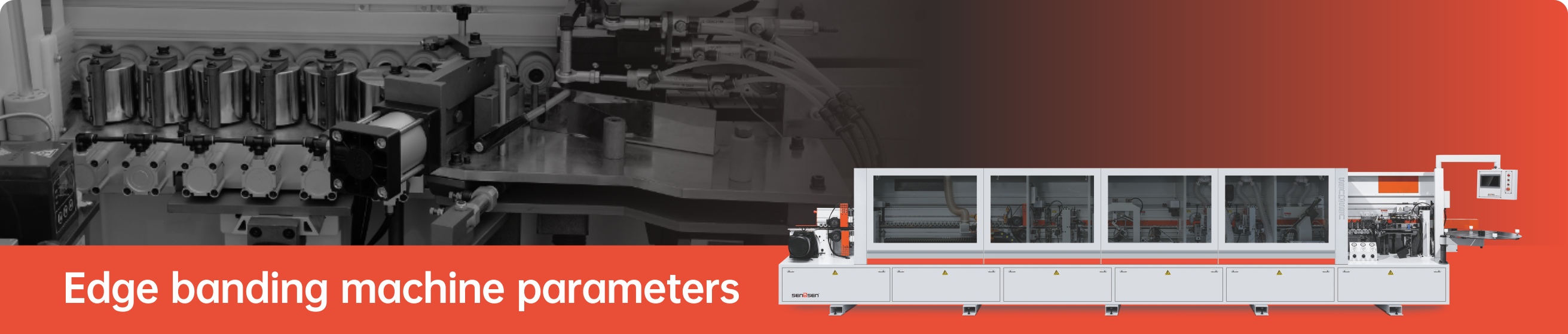

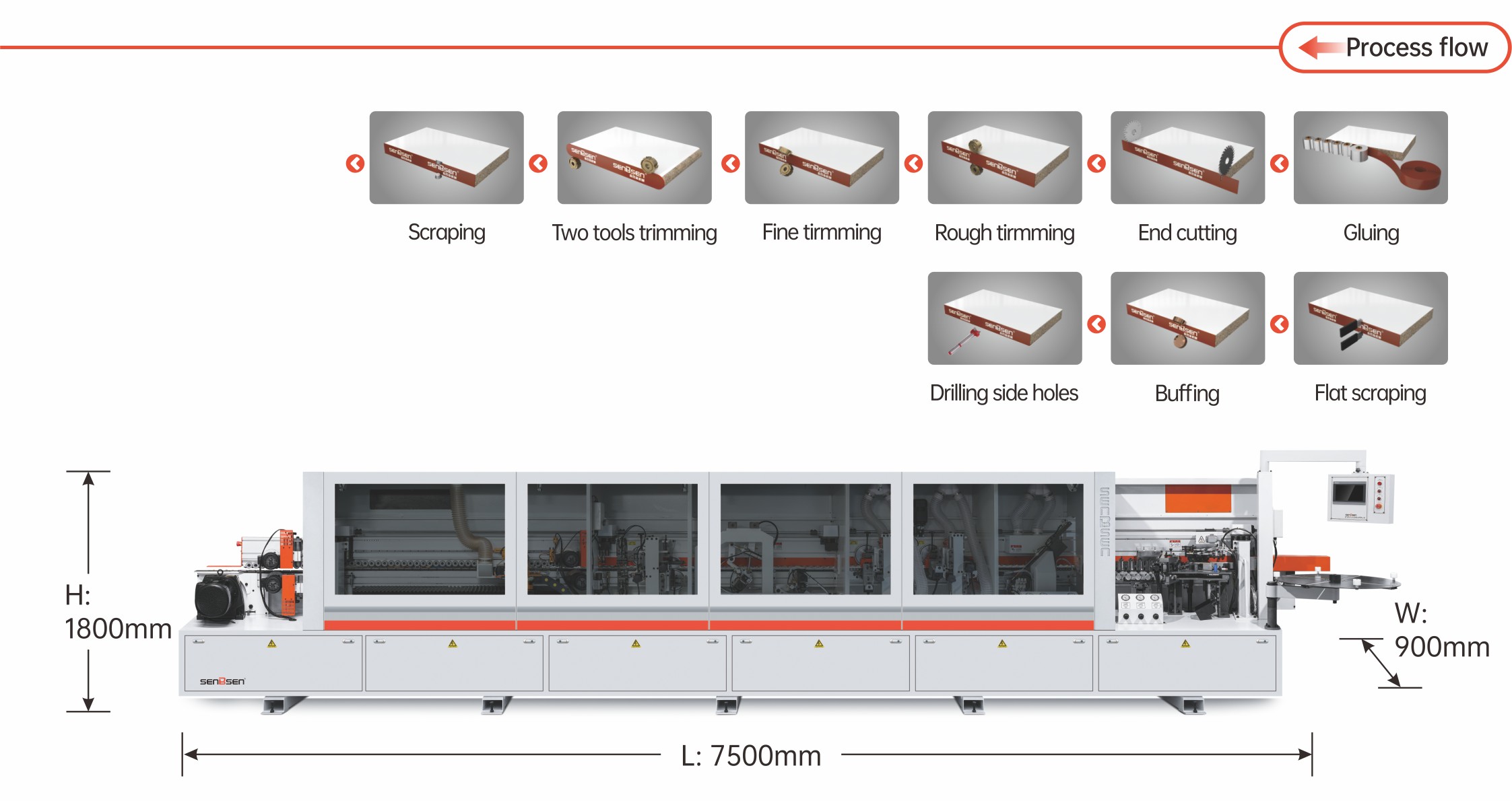

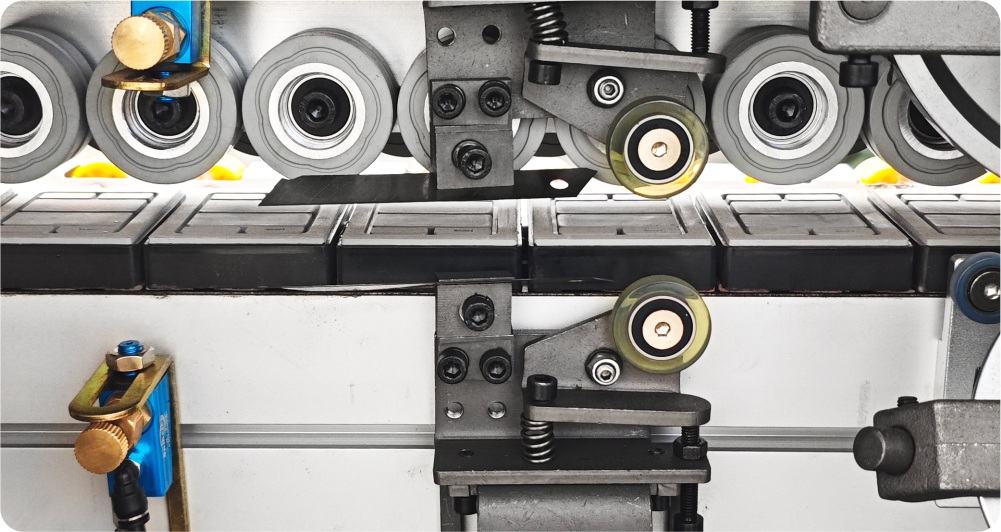

Strictly controlthe entire edge sealing process,including gluing > end cuting > rough tirmming > fine tirmming > two tools trimming > scraping > flat scraping> bufing > driling side holes; After multiple rounds of qualty inspection and repeated debugging, we have achieved smooth and firm edge sealing with perfect details, providing a solid guarantee for furniture quality.

|

Model |

SBS - 668 Heavy duty fully automatic edge banding machine |

||

|

Sheet length |

>120mm |

Input voltage |

380V |

|

Sheet width |

>40mm |

Input frequency |

50Hz |

|

Sheet thickness |

10 - 60mm |

Air pressure |

0.6Mpa |

|

Edge band thickness |

0.3 - 3mm |

Total power |

17.6kw |

|

Feed rate |

18 - 22m/min |

Machine size |

7500*900*1800mm |

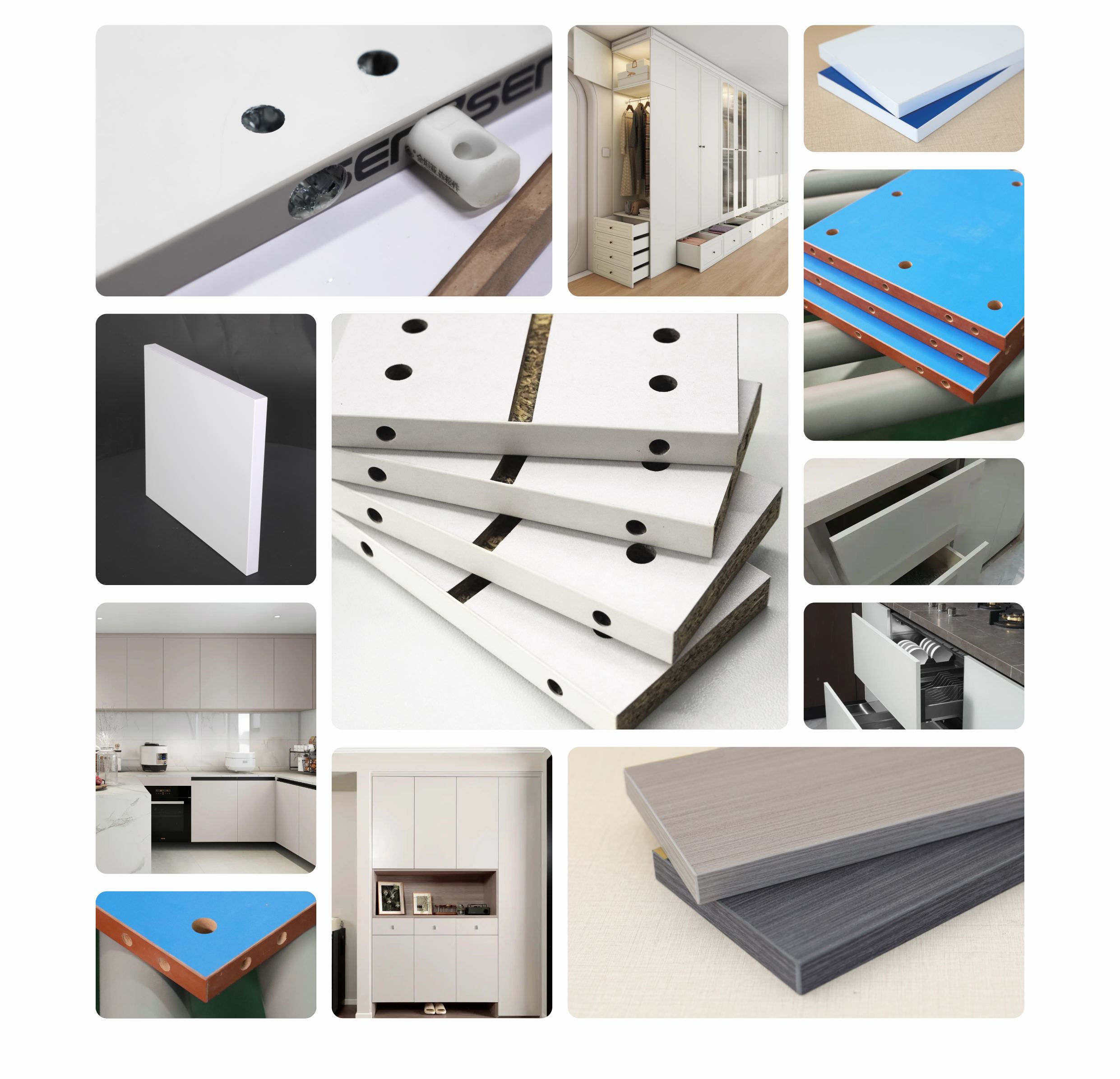

Various artificial boards such as density boards, particle boards, multi-layer boards, aluminum honeycomb boards, etc.;

batch customized furniture such as office furniture, cabinets, bathroom cabinets, etc.

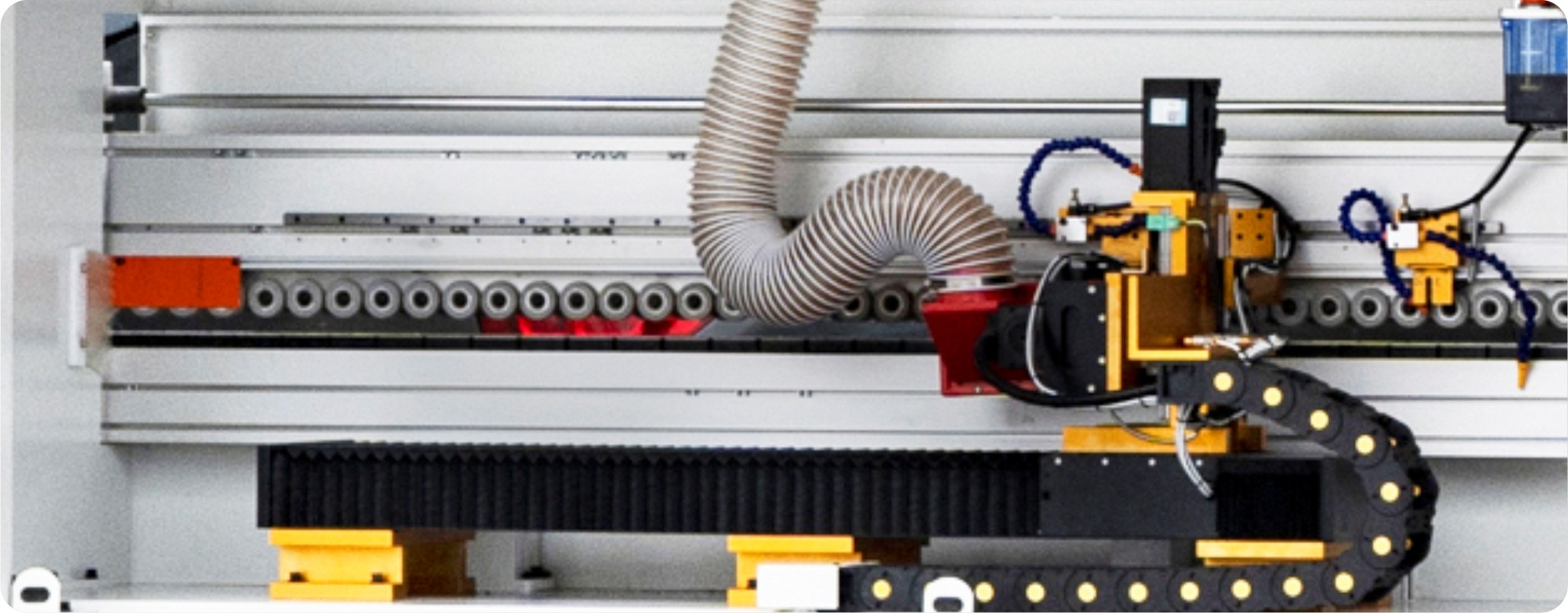

Integrated edge sealing and side hole

1. High precision side hole device, high accuracy of hole position recognition,fast response speed, high driling accuracy, stable performance,ensuring processing quality.

2.Servo drive, infrared induction, can complete side proceses such as three in one hole, wooden pin hole, blind hole, etc, while sealing the edge, with precise zero leakage, improving efficiency and reducing costs.

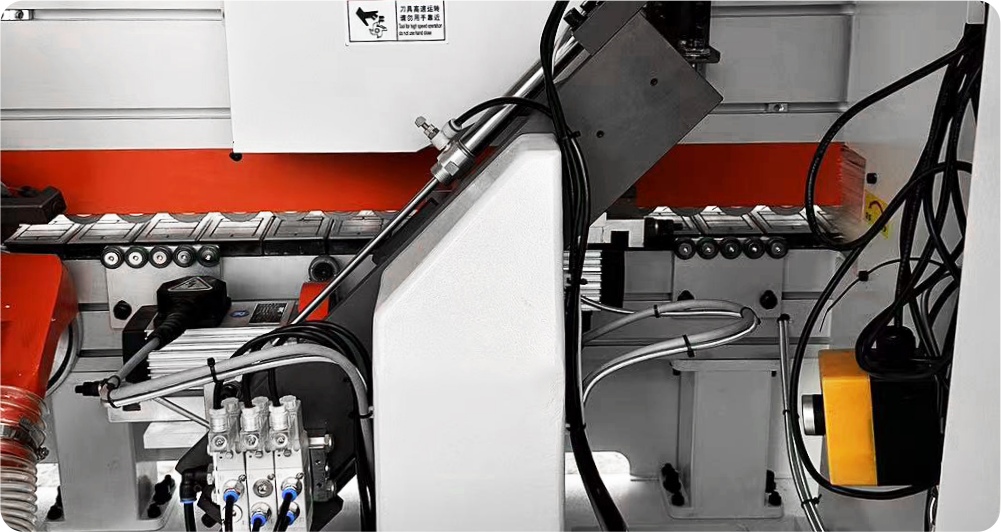

Glue coating device

Compatible with EVA/PUR adhesive, precise control of adhesive amount, uniform and thin coating, firm bonding, and good edge sealing effect.

End cutting

By precise linear guide movement, the edge banding at both ends of the front and rear can be quickly cut to improve the quality of the edge banding.

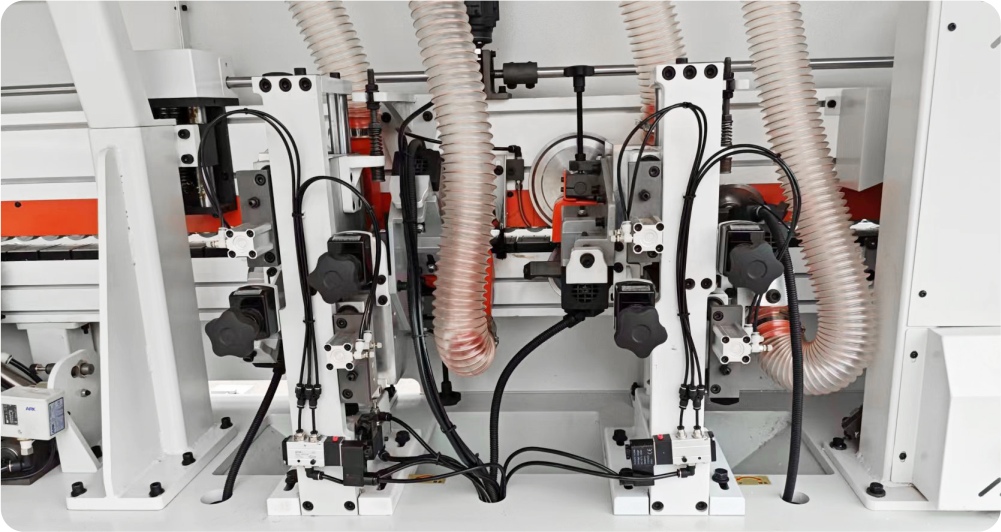

Rough and fine trimming

Cut off the excess edge bands on the upper and lower surfaces of the protruding board, so that the upper and lower edges of the edge banding are flush with the upper and lower surfaces of the board.

Flexible flat scraper

Scrape off the remaining adhesive and trim the edge strip on the board that has been edge sealed, without damaging the board, to improve the quality of edge sealing.