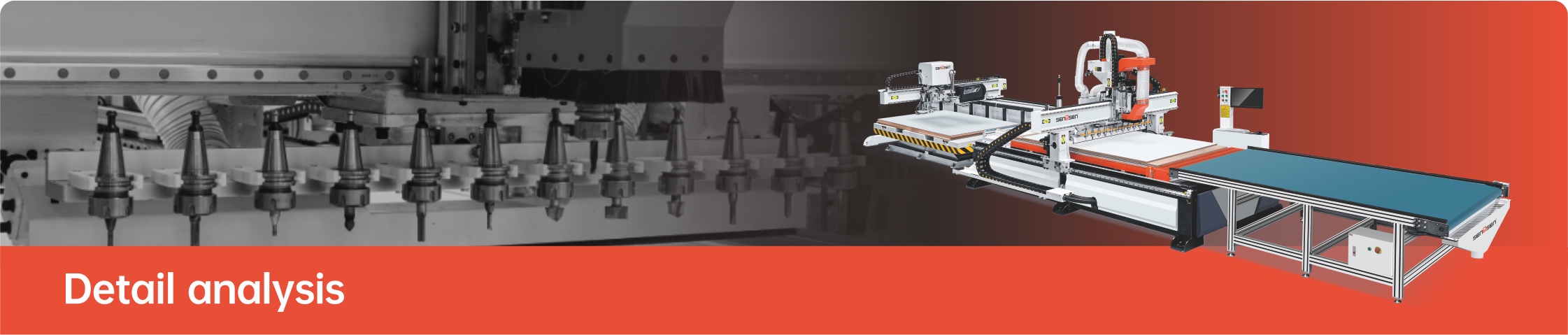

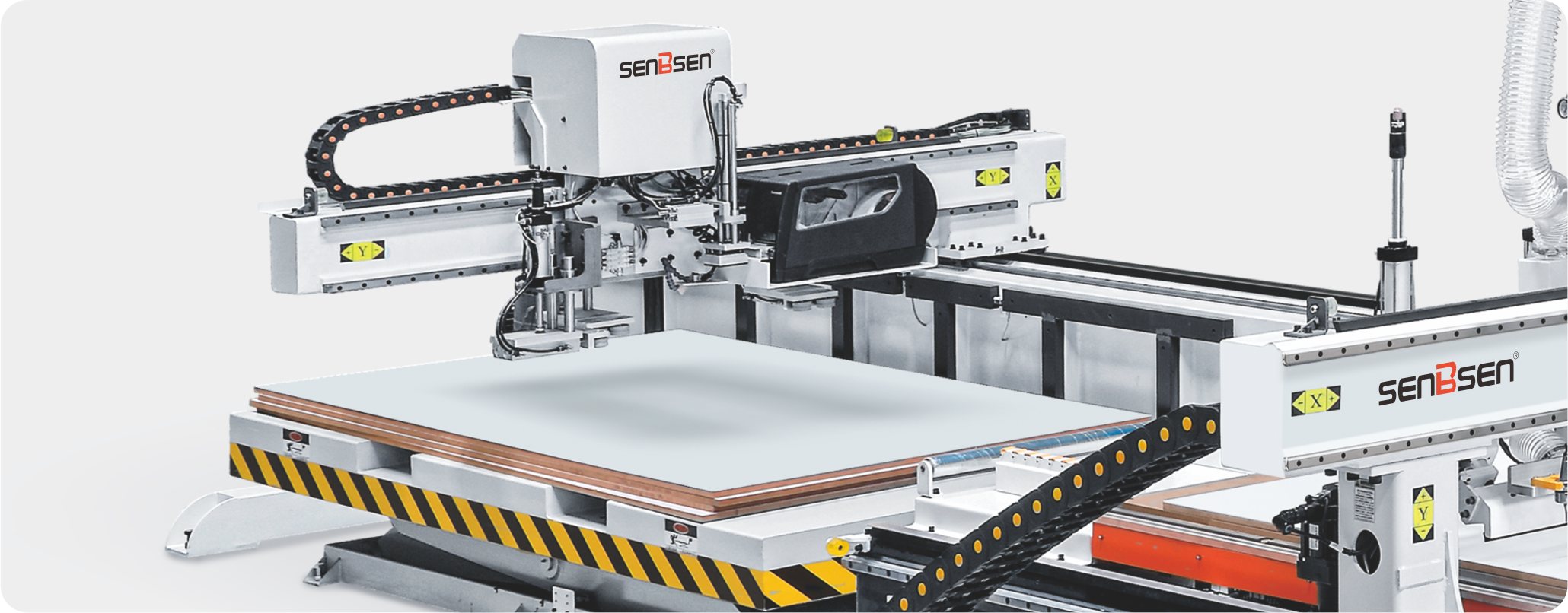

Inteligent central integrated contro, automatic labeling, automatic loading and unloading, automatic processing, can be completed by only one person throughout the process, achieving automation and intelligence, saving labor costs, and reducing the dificulty and error rate of manual operation.

|

Model |

SBS-TH9-12 CNC cutting production line (with label) |

|

Processing Size |

2440/2800*1220mm |

|

Material Processing Speed |

8 - 20m/min |

|

Spindle Power |

9.0kw Air cooled spindle |

|

Vacuum Pump Power |

11kw |

|

Spindle Speed |

18000r/min |

|

Total Power |

25kw |

|

Traveling Speed |

65 - 80m/min |

|

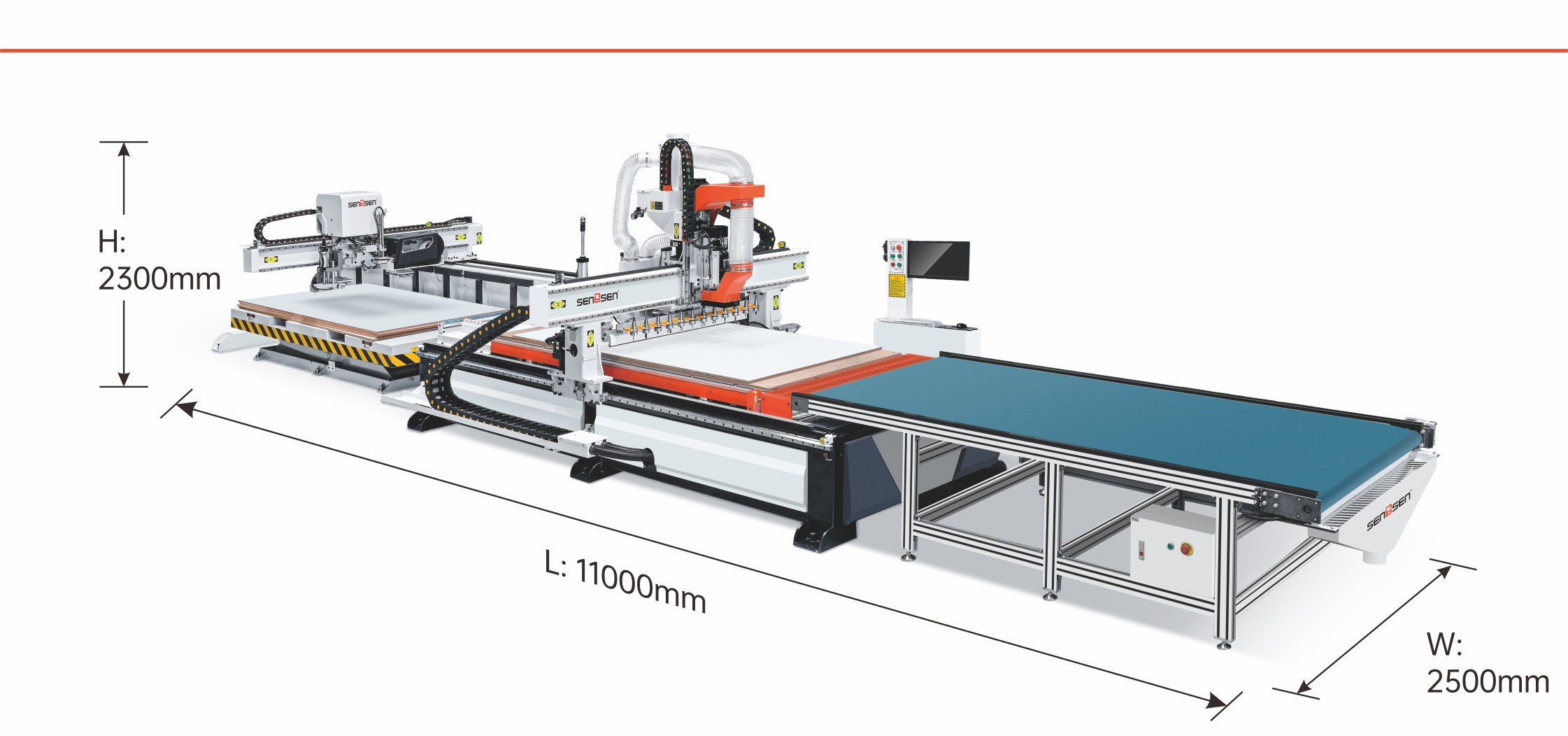

Overall Dimension |

11000*2500*2300mm |

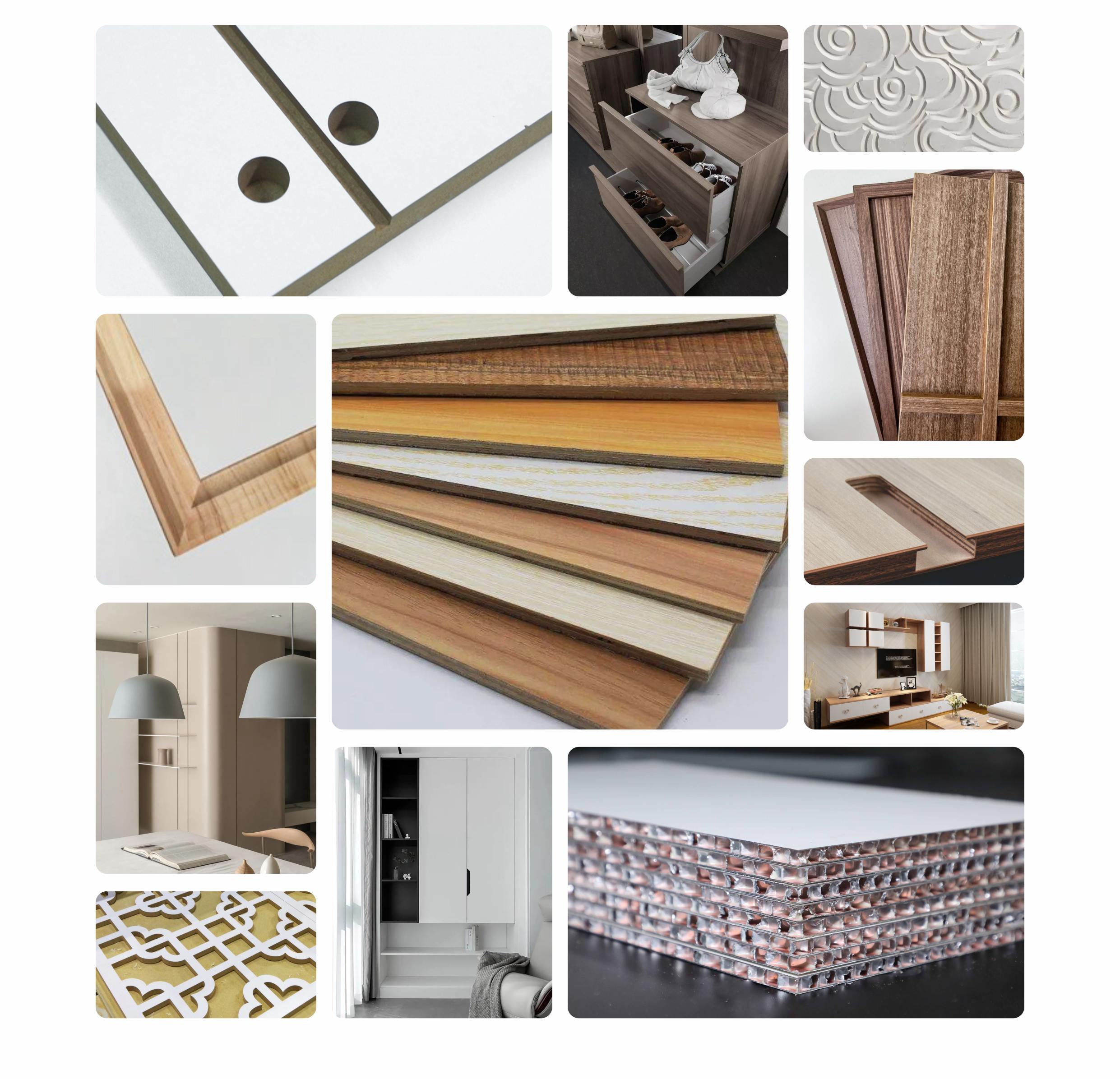

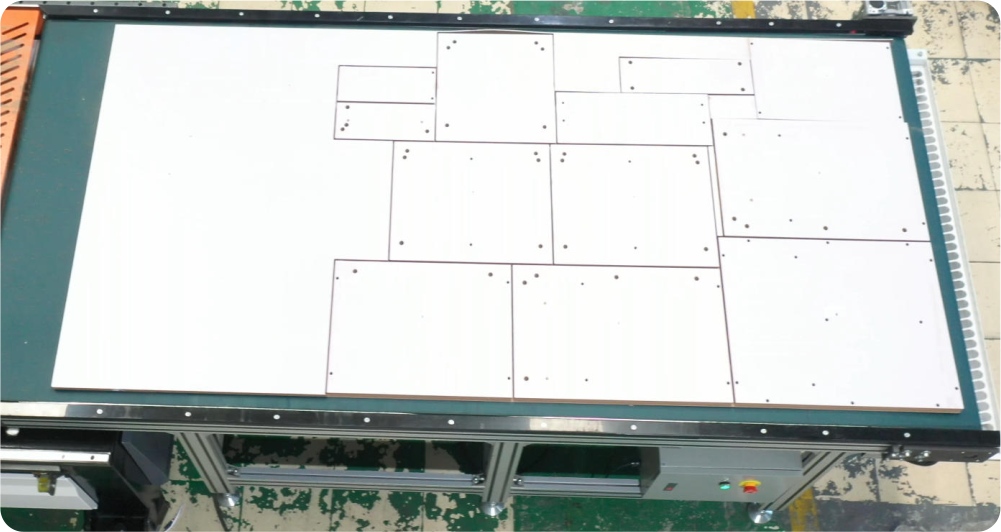

The machine can automaticaly complete the labeling, driling, slotting, cuting, and cuting of the board as an integrated procesing equipment. No need for manual flipping, double-sided punching and slotting can be completed in one go.

Integrated loading and labeling

1. High degree of automation, achieving automatic loading/labeling/processing/unloading, simplifying processes, and optimizing workflows.

2.90 degree intelligent rotating labeling, which can automatically adjust the direction according to the board and guicky label, efficient and stable, avoiding the cutting area of the board and protecting the label.

3. Automatic loading on the lifting platform saves labor costs and is convenient and fast.

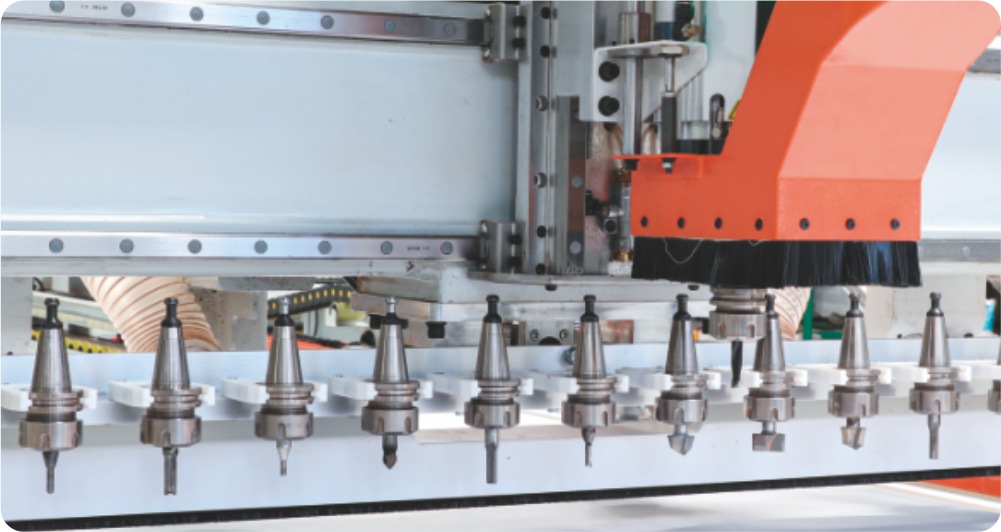

Direct automatic tool changer magazine

12 straight rows of knives in the magazine, freely switchable, suitable for processes such as drilling, slotting, milling, carving, cutting, and three in one invisible parts. Multiple shapes can be completed at once.

Accurate knife alignment device

Effectively avoiding manual tool alignment errors, intelligently detectingtool length, and improving efficiency and accuracy.

Auxiliary feeding rubber wheel

After the auxiliary workpiece labeling is completed, it is moved to thecutting machine to protect the surface of the board, prevent scratches,and ensure production quality.

Automatic feeding

Belt conveyor for material feeding, combined with push plate feeding,saves labor, is convenient and fast, and seamlessly connects with subsequent processes.